- GreenMatch

- Is Polyester Bad For The Environment? Statistics, Trends, Facts & Quotes

Is Polyester Bad For The Environment? Statistics, Trends, Facts & Quotes

In a world where every third piece of clothing is likely made of polyester, this synthetic fibre has woven its way into the fabric of our lives. But at what cost? Polyester, a petroleum-based product, has been under the microscope recently due to its significant environmental footprint.

It is the world's most commonly used fibre, accounting for 52% of fibres produced globally in 2020. This seemingly innocuous material, celebrated for its lightness, strength, and wrinkle-free nature, hides a darker side.

Polyester's production process is energy-intensive, requiring as much as 125 MJ/kg of polyester fibre, resulting in 27.2 kg CO2 eq/kg of polyester woven fabric emission. Yet, these staggering numbers are just the tip of the iceberg.

Moreover, the poor management of residues along the supply chain can cause soil and water pollution. These microplastics harm marine life and can eventually make their way up the food chain, threatening human health.

Furthermore, longevity is a double-edged sword. While it allows clothes to be worn many times, it also means that these garments will likely end up in landfills, where they can take hundreds of years to break down.

Despite these alarming facts, the use of this material continues to grow, fueled by its relative cheapness and the rise of fast fashion.

"Is Polyester Bad For The Environment? Statistics, Trends, Facts & Quotes" aims to peel back the layers of this ubiquitous material. We will dive deep into the polyester world through hard-hitting statistics, current trends, undeniable facts, and poignant quotes from industry leaders and environmentalists.

What Do We Mean With Polyester Exactly

Polyester comes in many forms, but for this article, we are talking about two specific types of polyester:

PET can be used alone or blended with other fabrics to make wrinkle-free, stain-resistant clothing that can retain its shape.

Polyester is used in an incredible amount of everyday things, for example:

Environmental Impact of Polyester

The environmental impact is in several ways, but the main problem is microfibers. Or specifically, microfibres getting into the bodies of animals, marine life and humans.

The estimation is that 0.5 million tonnes of plastic microfibers are shed yearly during the washing of textiles based on plastics like polyester, nylon or acrylic, which end up in water, rivers and the ocean.

This isn’t polyester only, but it will be a large part of the 0.5 million ton. Based on the growth of the plastic industry, this might be even 0.7 million tons by 2050.

The accumulated amount entering the ocean between 2015 and 2050 would exceed 22 million tonnes. This is according to the research of the Ellen Macarthur Foundation.

Here are some of the most important statistics and research about microfibres:

Seventy-three (75) per cent of fish caught at mid-ocean depths in the Northwest Atlantic have microplastic in their stomachs. Even the animals living in the Mariana Trench, the deepest ocean part (source).

It also underscored how this is a global problem: Synthetic textiles are more common in developing nations, which often don’t have robust wastewater treatment facilities to filter them out.

The second sizeable environmental impact is on the workers producing the polyester.

High cost and time pressures are often imposed on all parts of the supply chain, which can lead to garment workers suffering poor working conditions with long hours and low pay, with evidence, in some instances, of modern slavery and child labour. Many workers face dangerous working environments due to hazardous processes, substances of concern used during production, unsafe buildings, or lack of safety equipment.

Then there is the problem of local pollution as factories discharge untreated production wastewater, polluting local rivers.

But the production comes with more problems. Material and water usage is set to become increasingly problematic. With water usage, the most significant challenge will be accessing the water that the textiles industry relies on in water-scarce regions.

For example, the production often uses antimony trioxide as a catalyst, which is retained in the polyester fibres. Antimony trioxide is suspected of causing cancer in humans if inhaled.

Polyester is made from oil, a non-renewable resource and a significant source of pollution. It also requires a lot of energy to create.

Then, finally, one more huge problem that most synthetic materials have: the average polyester product degrades in over 200 years. Meaning it will fill landfills for centuries to come.

One of the best alternatives to polyester is recycled polyester. Recycled material production reduces CO2 emissions by 75% compared to virgin polyester production, making it better for the environment.

Is Polyester Sustainable?

Is polyester sustainable? It is not sustainable. It doesn’t degrade and is relatively hard to recycle. Once created, it will be on this earth for over 200 years. Finally, it sheds microfibres so small that it is hard to detect while doing considerable environmental damage.

Is Polyester Toxic?

Since polyester is made of plastic, it is not biodegradable. It takes hundreds of years for the fibre to dissolve. When sent to landfill, the toxic materials used during production leach into the soil and could contaminate the local population's water.

Can You Recycle Polyester?

Virgin polyester (PET) can be recycled into RPET but cannot be recycled anymore.

But this is harder when the polyester is blended with other fabrics like cotton, metal or other synthetic materials.

Also, it is tough to recycle it at scale. Therefore, the majority is burned. And with that, it releases carbon and the chemicals that are in the materials.

One Japanese factory operating at a commercial scale will recycle their polyester from Patagonia into fresh polyester. The rest of the global output can’t be recycled at a cost acceptable to fashion brands using today’s technology (Eco Consult).

Is Polyester Biodegradable?

Polyester is not biodegradable, meaning it can take hundreds of years to break down if it ends up in a landfill. More than 200 even.

What Are Polyester Alternatives?

RPET is already an alternative to PET.

Other alternatives are other materials that are biodegradable or easier to recycle:

There is an extensive list of alternatives here: a list of sustainable fabrics.

Polyester Statistics, Trends, Facts and Quotes

Between 2000 and 2014, global clothing production has doubled. In 2002, demand for polyester surpassed cotton (McKinsey).

In 2020, 57.7 million tons of polyester were produced (Textile exchange).

The % of RPET increased from 11% in 2010 to 15% in 2020 (8.4 million tons) (Textile exchange).

The global polyester fibre market (PET) is valued at 90.6 billion US dollars and is projected to grow to 150 - 170 or even 230 billion in 2030 at a CAGR of 7.5 - 9.21%.

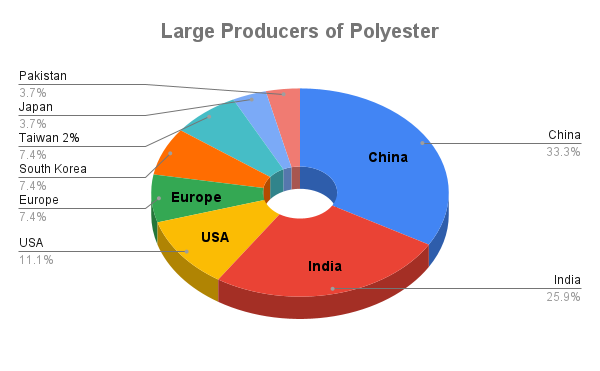

China is the largest manufacturer of polyester, with 73% of the total production (full disclosure, this is actually “chemical fibre production” that includes polyester, but this will also be true for polyester).

Significant large producers are shown in the image below.

The USA and Turkije also produce, but smaller amounts.

The total global production capacity is about 53.7 million metric tons.

53% of all fibres produced globally are polyester (Textile exchange).

15% of that is from RPET

What do people say about polyester

If we can bring emissions from polyester to zero or negative value, we can significantly reduce industry emissions.

Benoit Illy, co-founder and CEO of French start-up Fairbrics

Polyester is the most widely-used clothing fibre in the world, but as a synthetic material made from plastic, polyester needs a lot of energy to produce and is highly water and air-polluting.

Roger Lee, CEO of clothing manufacturer TAL Apparel

The fashion industry is at a tipping point. Despite its environmental impact, the wide use of polyester calls for brands to take responsibility and explore alternatives like recycled fibres.

Annoymous Fashion Analyst

Polyester is a synthetic material that is loved for its ability to be both a natural fiber and a material for a wide range of applications such as a backpack, sports bag, and cooler bags.

kelvincorp

Frequently Asked Questions

Polyester is a synthetic fibre derived from oil and the most commonly used fibre worldwide. It is light, strong, easily dyed, and can be woven or knitted. It is also easily blended with other fibres. Its easy-to-wash, wrinkle-free nature made it revolutionary when it first emerged in the 1970s. Its relative cheapness has fuelled the growth of fast fashion.

Yes, polyester is bad for the environment. It is a type of plastic that takes a long time to decompose and releases significant carbon emissions during production. The microfibers shed from polyester clothing can also harm the environment by entering water bodies and affecting marine life.

Polyester is widely used in clothing due to its soft texture, durability, and cost-effectiveness. However, the environmental impact of its production and disposal is increasingly leading the fashion industry to explore more sustainable alternatives.

Environmentally friendly alternatives to polyester include natural fibres like wool, cotton, and hemp and sustainable synthetic fibres like recycled polyester, Tencel, polylactic acid (PLA), Sorona, and Econyl.

Yes, polyester can be recycled, but it is a problematic and energy-intensive process that needs to be more widely practised. The quality of recycled polyester is almost just as good as virgin polyester. However, it is essential to note that even recycled polyester is still non-biodegradable and takes years to disappear once thrown away. It also still releases plastic microfibers, making it less environmentally friendly.

Natural fibres like cotton or linen are alternatives to synthetic materials like polyester. These natural fibres are biodegradable and do not release microfibers into the environment. However, each fibre has advantages and disadvantages; the choice primarily depends on the end-use and attributes needed.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?