Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Get Free quotes from insulation specialists near you

Save money by comparing quotes and choosing the most competitive offer

The service is 100% free and with no obligation

- GreenMatch

- Insulation

- Wall Insulation

- External Wall Insulation

- External Insulation Render

External Insulation Render: What Is It, Best Types & Costs

- The average cost of external insulation render is between £3,000 and £5,500 for a typical three-bedroom terraced house.

- Insulated rendering provides some thermal benefits, but it is most effective when combined with external wall insulation, which can save up to 35% of the heat in your home.

- Numerous insulation renders are available, but the top choice is silicone, a flexible, breathable, and water-resistant material.

Uninsulated walls are a significant cause of up to 35% of your home's heat loss—more than any other part of the house. This results in higher energy bills and a significant increase in your carbon footprint, all because your walls aren't effectively retaining heat. The good news is that addressing this issue can save you money and make your home more eco-friendly.

Home insulation for your walls is one of the most effective ways to tackle heat loss, potentially reducing your carbon footprint by up to 2,100 kg each year and lowering energy bills by as much as £700. While the costs of full external wall insulation can be high, more affordable options are available.

One cost-effective solution is external insulation render, which improves heat retention and adds a protective layer against the weather while boosting your home's curb appeal. Whether you're looking for an economical insulation method or an extra layer for a full external wall insulation project, this guide covers everything you need to know—benefits, costs, materials, and more.

Time and money are precious, so why waste either on endless quote comparisons for external insulation renders? Let GreenMatch do the work for you! In just 30 seconds, you can fill out a simple form, and we’ll connect you with up to four free quotes from top insulation specialists in your area—no hidden costs, no obligations. Click below to learn more.

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

What is external insulation render?

External insulation render is the finishing layer of an external wall insulation system, designed to protect the insulation while significantly improving a building's thermal performance by reducing heat loss. This system includes insulation material, a reinforcing mesh, a render base, and a final finishing coat that enhances energy efficiency and durability.

Beyond its insulation benefits, external insulation render improves the overall aesthetic of your home by adding a smooth, contemporary finish. It increases durability and weather resistance, protecting the external insulation from harsh elements. This makes it a popular choice for homeowners upgrading their property's functionality and appearance.

However, external insulation render isn't exclusive to external wall insulation systems. It can be applied directly to the bricks or blocks of your home, even without insulation. Additionally, rendered walls can have insulation added to it in the future.

This provides an affordable way to enhance your home's durability, appeal, efficiency, and weather resistance without full insulation.

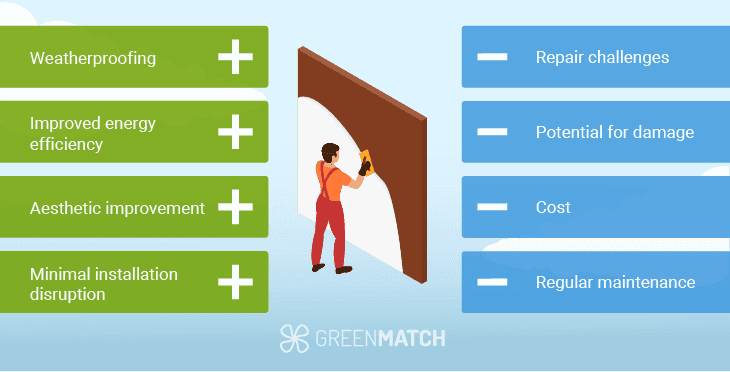

Pros and cons of rendering insulation

Rendering insulation offers several benefits, but it's important to weigh the potential drawbacks to decide if it's the best option for your home. Here are the pros and cons of external insulation render:

Pros of rendering insulation

- Improved energy efficiency: External insulation render can help reduce heat loss, maintain a stable indoor temperature, and lower energy costs. According to RealHomes, applying render can lead to up to 40% energy bill savings.

- Weatherproofing: The render provides an additional layer of protection against wind, rain, and other weather elements, extending the lifespan of your home’s exterior.

- Aesthetic improvement: Render can give your home a fresh, modern appearance. It comes in various finishes and colours, allowing for customisation to enhance curb appeal.

- Increased property value: Installing external insulation improves your home's energy efficiency and enhances its exterior appearance. These upgrades can significantly boost your property's market value by making it more attractive to potential buyers and increasing its energy rating.

- Minimal installation disruption: Applying external insulation render is relatively straightforward and causes minimal disruption to your daily routine. On average, the installation is completed in one to two days, allowing for a quick and efficient upgrade to your home..

- Noise reduction: External insulation render adds an extra layer to your home’s exterior, which helps to reduce external noise. While not a primary feature, this additional barrier can improve overall sound insulation, contributing to a quieter living environment.

Cons of rendering insulation

- Regular maintenance: External wall render requires periodic inspections to identify cracks or chips early on. While this maintenance helps prevent issues, it can be time-consuming and adds to the long-term upkeep of the home.

- Potential for damage: If the external insulation render is not maintained correctly, it can develop cracks or chips over time, leading to potential damage and costly repairs. Regular care is essential to ensure the render remains in good condition and protects the underlying insulation

- Repair challenges: Should the render need repairs, matching the original colour and texture can be difficult. This can result in visible differences between the old and new render, potentially affecting the overall aesthetic of your home.

- Cost: Although external insulation render is considered cost-effective, combining it with external wall insulation can be expensive. For example, installing external wall insulation on a typical three-bedroom semi-detached house, including the render, can cost around £11,000.

- Change in home’s appearance: While external insulation render can enhance the look of modern homes, it may alter the appearance of period properties with antique or unique finishes, diminishing their original charm and architectural appeal.

- Building regulations: Although most homes can add external insulation rendered under permitted development, it’s crucial to check with your local authority for approval, especially for listed buildings or those in conservation areas where such changes may not be permitted.

Types of insulated render

Insulated render systems come in various types, each with specific insulation materials and finishes designed to improve energy efficiency, protect against weather, and enhance the aesthetics of a building. Here’s a breakdown of the most common types of insulated render:

Cement render

Cement render is one of the most commonly used types of render, made from a blend of cement, sand, and water. It is applied to exterior walls to create a smooth, durable, and protective finish. Due to its widespread availability and ease of production, cement render is one of the most affordable options for insulation. Its inherent strength—cement being one of the strongest materials—enhances the durability of exterior walls, adding a robust, weather-resistant layer that protects against harsh elements.

However, cement render does come with some limitations. It is prone to cracking over time, requiring regular inspections to address potential issues early on. Additionally, the colour of cement can fade or develop a white efflorescence over time, necessitating reapplication or additional treatments, which can increase future maintenance costs.

Cement render also requires multiple layers—typically 2 to 3—to achieve a proper finish, adding between 16mm and 25mm in thickness of external wall insulation. This increased wall thickness can present spatial challenges for homes with limited exterior space or those sharing a boundary with neighbouring properties.

- Cost-effective

- Durable

- Weather-resistant

- Prone to cracking

- Increases thickness of exterior walls

- Regular maintenance required

Acrylic render

Acrylic render is a flexible and versatile option for external insulation, made from acrylic resin, sand, and water. It enhances a home's appearance and provides exceptional thermal efficiency compared to other render materials.

Typically requiring no more than two layers, acrylic render adds only 4 to 6mm to the thickness of external walls, making it an ideal choice for homes with limited exterior space. One of the key advantages of acrylic render is its high elasticity. This flexibility reduces the likelihood of cracking over time, minimising the need for future repairs and associated costs.

Additionally, it comes in a wide range of finishes. You can apply it in various textures, creating either a smooth or more textured appearance based on your aesthetic preferences. Another benefit is its quick curing time, typically requiring only a few days to set fully, making it a time-efficient choice.

Acrylic render is one of the more expensive options, increasing the overall cost of external wall insulation projects. It's best suited for homes in milder climates, as it isn't as waterproof as other renders. Its lower breathability makes it more prone to condensation, leading to mould and mildew growth if not managed properly.

- High elasticity

- Versatile finishes

- Thin render material

- High-cost

- Potential risk of mould and mildew

- Not suitable for harsh weather conditions

Silicone render

Silicone is a modern, high-performance external render known for its flexibility, durability, and water-repellent properties. Silicone render, made from silicone resin, is ideal for homes in wet climates due to its hydrophobic properties.

Its water-repellent nature prevents moisture penetration, causing rain to bead and roll off, reducing maintenance. Silicone remains breathable, allowing moisture to escape, which helps prevent condensation and dampness issues inside the building.

Its flexibility makes it less prone to cracking compared to other renders, offering long-lasting durability. It is also available in various colours and textures, allowing you to customise the render to fit your home's aesthetics.

However, silicone rendering is among the more expensive rendering options. Additionally it requires professional installation due to its complexity, making it less suitable for DIY projects.

- Water-resistant

- Self-cleaning

- Breathable

- Flexible

- Expensive

- Not suitable for DIY projects

Lime render

Lime render, made from lime, sand, and water, is valued for its breathability, flexibility, and compatibility with older buildings. Its breathability makes it perfect for older buildings needing ventilation to prevent condensation issues.

Lime render's flexibility adapts to natural building shifts without cracking, making it better suited for period properties than cement renders. Lime is also a sustainable choice, with a lower carbon footprint and the ability to absorb CO2 as it cures.

However, lime render requires more time to cure and is usually dry after 3 days. Additionally, it is less weather-resistant, requiring regular maintenance in areas with harsh climates. Despite challenges, lime render is preferred for conservation projects due to its natural finish and compatibility with traditional materials.

- Eco-friendly

- Suitable for historic buildings

- Flexible

- Breathable

- Long curing time

- Less weather-resistant

What is the best render for insulation?

Choosing the best render for insulation involves balancing your personal preferences, budget, and the specific needs of your home. Here’s a breakdown of the top insulating render options, each catering to different priorities:

- Most sustainable choice: Lime render is the most eco-friendly option, made from natural materials such as lime, sand, and water. Its low carbon footprint makes it an excellent choice for those prioritising sustainability, and it’s particularly suited for older or historic buildings due to its breathability.

- Most cost-effective choice: Cement render is the most affordable and widely available option for insulation. It provides strong protection against the elements and is easy to produce, making it a popular choice for homeowners on a budget. However, it may require more maintenance over time compared to other options.

- Overall best choice: Silicone render offers the highest performance, combining flexibility, durability, and superior water resistance. It is ideal for homes in harsh or wet climates and is self-cleaning, requiring minimal upkeep. Available in various colours and finishes, silicone render is versatile and long-lasting, making it the top choice for modern homes.

Ultimately, the best render for insulation depends on your specific goals. Consulting with a rendering specialist will help you choose the right solution, whether you are seeking an eco-friendly, cost-effective, or high-performance option.

If you’re ready to explore the best external insulating render for your home, GreenMatch can connect you with top local experts. Fill out our 30-second form, and we’ll provide up to four free, no-obligation quotes. Click below to learn more!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

External insulation render cost

External insulation render costs around £3,000 and £5,500 for a typical three-bedroom terraced house.

However, several factors will influence the final price, including the type of materials used, the size of the property, labour costs, and the overall complexity of the project.

Labour costs are a significant part of the total expense. On average, labour costs around £250 per person per day, and a project of this size usually requires two workers. It can take 5 to 8 days to complete the installation, depending on the intricacy of the project. Since labour is charged per day and person, the project's duration will directly affect the overall cost.

Materials also play a crucial role in determining the final price. Different insulation and render materials come with varying costs, each affecting the total. Below is a table that overviews the typical material costs of external insulation render projects.

| Material | Cost per m2 |

|---|---|

| Cement render | £10 per m2 |

| Acrylic render | £30 per m2 |

| Silicone render | £50 per m2 |

| Lime render | £20 per m2 |

The cost of external insulation render can vary significantly based on your choices. To ensure you get the best value for your budget, comparing quotes from multiple contractors is crucial. However, this process can be time-consuming and may not always yield the desired results. That's where GreenMatch comes in. With just a 30-second form, we can connect you with up to four free quotes from top external insulation render installers in your area, tailored to your needs and budget. Save time and effort - click below to learn more!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

FAQ

Yes, insulating render is an effective solution for improving your home’s energy efficiency, reducing heat loss, and enhancing both durability and aesthetics.

Render provides minimal insulation, but when combined with insulating materials in an external wall insulation system, it can significantly improve a building’s thermal performance.

Silicone render is often considered the best overall due to its durability, flexibility, and water resistance, while lime render is the most sustainable option, and cement render is the most cost-effective for basic needs.

Yes, external insulation can be applied to rendered walls, but the existing render must be in good condition or properly prepared to ensure the insulation adheres effectively.

Caoimhe is an experienced content writer and researcher who is passionate about providing accessible information to every reader. With a background in English literature and Sociology, she combines the two disciplines to create cohesive, well-thought-out, and well-informed pieces.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?