Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Get Free quotes from insulation specialists near you

Save money by comparing quotes and choosing the most competitive offer

The service is 100% free and with no obligation

- GreenMatch

- Insulation

- Wall Insulation

- Cavity Wall Insulation

- Injected Cavity Wall Insulation

Injected Cavity Wall Insulation: Types, Costs, Pros & Cons

- Insulating cavity walls is a cost-effective way to conserve energy. Up to 33% of heat loss occurs through walls; spray foam insulation can reduce this, cutting energy bills by up to 35%.

- The UK government promotes the use of spray foam in homes and offers funding through the ECO3 Scheme.

Adequate insulation is essential for improving your home's energy efficiency and comfort. Injected cavity wall insulation is a reliable way to lower heating costs and increase comfort levels at home. Up to 33% of heat loss occurs through walls, but utilising spray foam insulation can robustly mitigate this, leading to potential energy bill reductions of up to 35%. This guide provides an overview of the different types of injected cavity wall insulation and their costs, advantages, and potential disadvantages.

Are you considering home insulation? Let GreenMatch handle all the time-consuming research and screening for you. Skip the hours of searching and scheduling, complete our 30-second online form and receive up to 3 free quotes from trusted installers in your area. Click the button below to get started now!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

What is injected cavity wall insulation?

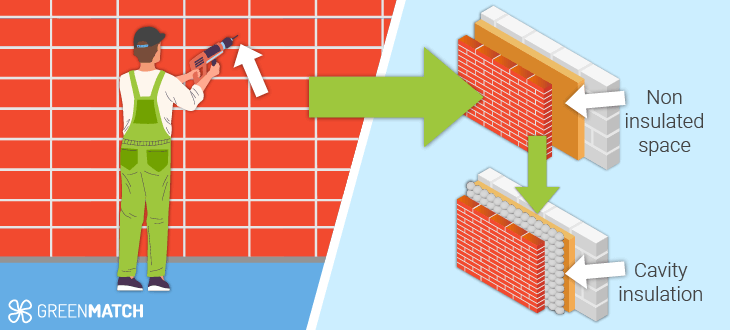

Injected cavity wall insulation insulates the hollow space (cavity) between your home's inner and outer walls. This technique is prevalent for retrofitting insulation in buildings, especially those constructed before the 1970s, which often lack adequate insulation.

The injection method, a safe and proven technique, starts with drilling small holes at regular intervals in the property's exterior walls. Through these holes, insulation materials such as mineral wool, polyurethane foam, or polystyrene beads are injected into the cavity using specialised equipment. The material fills the space, creating an effective barrier that reduces heat loss and improves thermal efficiency. The spray foam cavity wall insulation process is less messy and disruptive than typical insulation methods. The contractor will spray high-quality insulation foam directly into the cavity walls through a hole. This process is quick and causes little to no disruption.

When installed correctly and well-maintained, injected insulation can last 25-30 years or even longer. This durability allows homeowners to recoup their initial investment relatively quickly and subsequently enjoy ongoing savings over the long term.

Types of injected cavity wall insulation

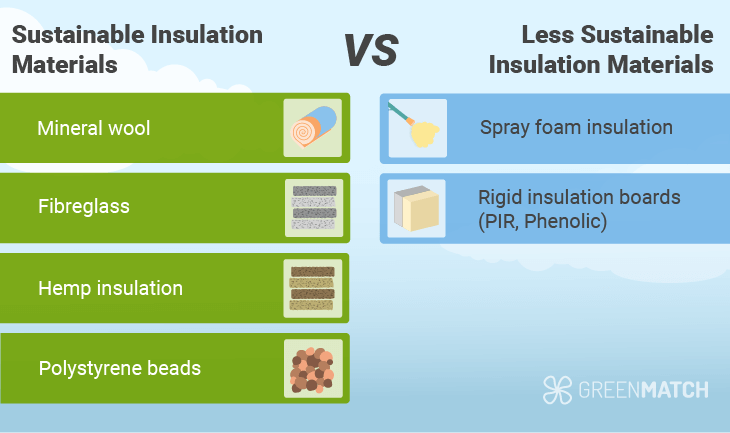

Injected cavity wall insulation is highly effective for upgrading older buildings by filling the void between the inner and outer walls with insulating materials. Below are facts of the three most popular types of insulation foam:

Mineral wool

Mineral wool is made from natural or synthetic minerals and is known for its excellent thermal and acoustic insulation properties. It is generally made from rock or slag.

Pros:

- Excellent thermal and acoustic insulation.

- Fire-resistant.

- Durable and long-lasting.

- Resistant to mould and mildew.

Cons:

- It can be more expensive than other options.

- Requires professional installation.

- It can settle over time, potentially reducing effectiveness if not installed correctly.

Mineral wool insulation is often made from recycled materials, making it a sustainable choice. It is non-toxic and safe for the environment and can also be recycled at the end of its life, making it eco-friendly. In terms of cost, mineral wool is relatively expensive compared to other insulation materials. However, its efficiency in reducing heat loss and improving energy justifies the investment.

Polystyrene beads

Polystyrene beads, with their unique properties of being small, lightweight, and easily fillable, offer a distinct advantage in insulation. Their common use with adhesive further enhances their ability to prevent movement within the cavity.

Pros:

- Good thermal insulation.

- Lightweight and easy to handle.

- Quick and easy to install.

- Resistant to moisture.

Cons:

- It is less effective as an acoustic insulator.

- It can be less durable compared to other materials.

- This may pose environmental concerns due to plastic content.

Polystyrene bead insulation is not biodegradable and can be challenging to recycle, which could contribute to plastic pollution if not disposed of properly. Despite this, it is generally cheaper than other insulation materials, making it a cost-effective option for those on a tight budget. While polystyrene beads are suitable for thermal insulation, they are less effective for soundproofing, so this may be a factor to consider, depending on your specific needs.

Polyurethane foam

Polyurethane foam insulation, with its unique properties, expands and fills the cavity completely, creating a tight seal that minimises heat loss and air infiltration. This makes it the perfect choice for your insulation needs.

Pros:

- High thermal resistance.

- Expands to fill gaps and cracks, securing a complete seal.

- Lightweight and strong.

- Resistant to water and mould.

Cons:

- It can be expensive.

- Requires professional installation.

- Potential health hazards during installation due to off-gassing.

Polyurethane foam insulation is mainly produced from petrochemicals, which are non-renewable resources, raising sustainability concerns. Specific polyurethane foam formulations may emit harmful gases during application, although modern formulations try to minimise this environmental impact. Moreover, it isn't easy to recycle after use, adding to its ecological footprint. Polyurethane foam insulation is pricier than other materials.

Injected cavity wall insulation cost

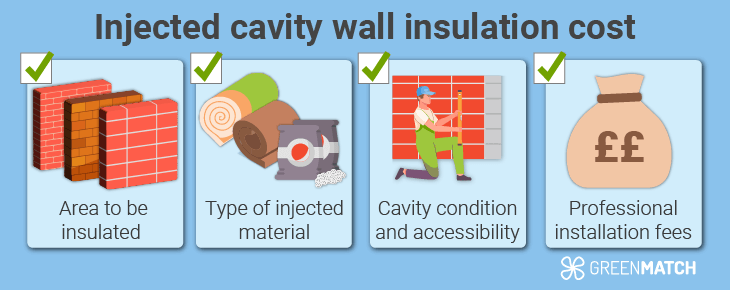

On average injected cavity wall insulation cost usually ranges from £20 to £40 per square metre. However, the total cost of cavity wall insulation depends on several factors:

- Area to be insulated (m²): Larger areas will naturally incur higher costs.

- Type of injected material: Different injected materials have varying costs.

- Cavity condition and accessibility: Complex installations or hard-to-reach areas can increase labour costs.

- Professional installation fees: Requires expertise, which adds to the cost.

| Injection material | Cost per m² | Average total cost |

|---|---|---|

| Polyurethane (PU) Foam | £20- £40 | £1,000 - £1,500 |

| Polystyrene beads | £10 - £20 | £500 - £1,500 |

| Mineral wool | £15 - £25 | £900 - £1,250 |

It's essential to consult a qualified insulation professional who can provide an accurate quote customised to your specific needs. Get a local installer to QUOTE now!

Injected cavity wall insulation problems

Injected cavity wall insulation greatly improves home energy efficiency and comfort. However, improper installation can lead to several potential issues that affect insulation performance and the wall's structural integrity. Professional cavity wall insulation installation is essential to secure good insulation and long-term durability for your home.

Settlement

Settlement happens when insulation materials within the cavity wall settle over time, unfortunately creating gaps and reduced insulation effectiveness. This problem typically happens from improper installation, where the insulation material is poorly distributed during the injection.

Moisture

Improperly installed insulation can cause moisture to seep, leading to cavity wall insulation damp and structural problems. This issue appears when insulation materials aren't appropriately sealed or when moisture barriers are compromised during installation.

Thermal bridging

Thermal bridging happens when the insulation layer is compromised due to gaps or incorrectly installed insulation around structural elements such as windows. This leads to localised heat loss or gain, reducing the insulation system's thermal effectiveness.

Air leakage

Incorrectly installed injected cavity wall insulation may not effectively seal air leaks, allowing air infiltration that compromises energy efficiency. This issue can happen from bad sealing around injection holes or improper installation techniques that fail to make airtight seals.

Structural damage

In extreme cases, improper installation of injected cavity wall insulation can provoke structural damage. This includes wall bowing or cracks due to excessive pressure from injected materials or wrong drilling techniques.

Trust professional installation

Hiring experienced professionals is critical to avoiding these common problems associated with injected cavity wall insulation. Professional installers use proper installation techniques and provide warranties and assurances against potential issues, providing homeowners with long-term performance and peace of mind.

Pros and cons of cavity wall insulation injection

Cavity wall insulation injection unquestionably improves energy efficiency, thermal comfort, and noise reduction between properties. Its rapid installation with minimal disruption promises long-term energy savings on heating and cooling costs. Still, it comes with potential settlement issues over time, improper installation techniques, moisture problems if not correctly installed, thermal bridging around structural elements, air leakage risks and possible structural damage.

For best results and to minimise potential risks associated with cavity wall insulation injection, homeowners must prioritise professional installation by qualified contractors with experience in insulation projects. This guarantees complete sealing, efficient material distribution, and strict compliance with industry standards, finally improving insulation performance and durability.

Is injected cavity wall insulation a good solution for your home?

Injected cavity wall insulation can be a worthwhile solution for your home, depending on your budget and the type of walls in your home. It delivers advantages like energy efficiency, improved thermal comfort, and noise reduction, making it perfect for many homeowners. However, the decision should consider potential flaws such as settlement issues, moisture risks, and the mandatory need for professional installation. Considering these aspects with the guidance of insulation experts can help decide if injected cavity wall insulation is the right choice for your home.

Are you thinking about home insulation? Let GreenMatch do the research and screening for you. Say goodbye to hours of searching and scheduling. Fill out our 30-second online form and get up to 3 free quotes from trusted installers in your area. Click below to get started now!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

FAQ

Injected cavity wall insulation can last several decades, giving sufficient thermal and acoustic insulation throughout its lifespan. Consistent maintenance and inspections are necessary to guarantee its steady performance.

The method of injecting cavity wall insulation consists of drilling small holes into the external wall of the property at regular intervals. Specialised equipment is then used to inject insulating material like foam or beads into the cavity between the inner and outer walls. This professional process secures coverage and adequate insulation.

With its high thermal resistance and effectiveness in reducing heat loss, injection foam insulation is a worthwhile investment as it provides a tight seal, minimises air leakage, and improves energy efficiency, leading to long-term savings on heating costs.

The cost of foam cavity wall insulation typically ranges from £20 to £40 per square metre. The total expense for injected cavity wall insulation varies based on area size, material choice, and installation complexity, influencing insulation costs. Professional installation is crucial for better performance.

Akif is a copywriter at GreenMatch since 2023. With a keen interest in community sustainability, green solutions and the role of digital media in identifying climate trends, he aims to hone in on his background in International Studies and Digital Media to provide a multidisciplinary approach to written content rooted in credible research and accuracy.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?

- Injected Cavity Wall Insulation: Types, Costs, Pros & Cons

- What is injected cavity wall insulation?

- Types of injected cavity wall insulation

- Injected cavity wall insulation cost

- Injected cavity wall insulation problems

- Pros and cons of cavity wall insulation injection

- Is injected cavity wall insulation a good solution for your home?

- FAQ