Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Get Free quotes from insulation specialists near you

Save money by comparing quotes and choosing the most competitive offer

The service is 100% free and with no obligation

- GreenMatch

- Insulation

- Shed Insulation

- Shed Roof Insulation

Shed Roof Insulation: Benefits, How to Install & Materials

- Nearly 25% of heat is lost through the roof, making shed roof insulation essential for reducing energy consumption and maintaining a comfortable environment year-round.

- Insulating your shed roof prevents condensation, which can lead to mould and rot, safeguarding your tools and stored items from moisture damage.

- Shed insulation installation costs range from £670 to £1,600, depending on shed size, chosen materials, and professional installation.

Shed roof insulation is crucial to maintaining a comfortable and energy-efficient space, whether your shed is used for storage, as a workshop, or even as a home office. With an estimated 9.6 million homes in the UK featuring a shed and 52% of the population owning one, ensuring proper insulation can lead to significant savings and added comfort.

Nearly 25% of heat is lost through the roof, making it one of the most critical areas to address when considering insulation for your shed. By insulating your shed roof, you can retain warmth during colder months, protect against overheating in the summer, reduce energy consumption, and even extend the lifespan of the shed structure and the items stored within.

In this guide, we'll explore the key benefits of shed roof insulation, the materials you can use, the associated costs, and a step-by-step process for installation.

If you're ready to take the next step toward insulating your shed, GreenMatch can help! Fill out a 30-second form, and you'll receive up to four free quotes from top roof insulation installers in your area. Get started today and make your shed more energy-efficient in no time! Click below to learn more!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

Why insulate a shed roof

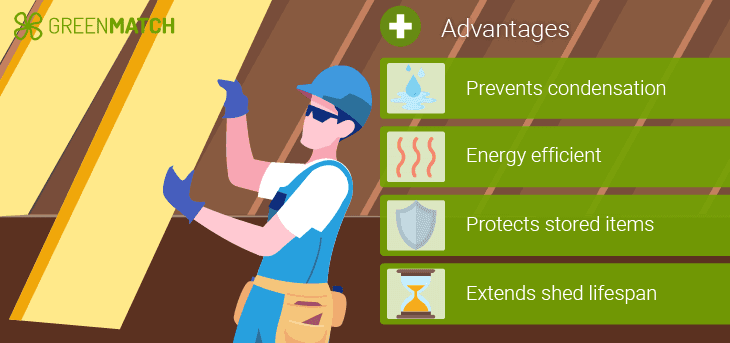

Shed roof insulation offers several benefits beyond regulating temperature. Whether your shed is used for storage, as a workshop, or a hobby space, properly insulating the roof improves its functionality and protects its contents. Here are the key advantages of shed roof insulation:

- Prevents condensation: Condensation happens when warm, moist air hits a cold surface, forming water droplets that can lead to mould and rot. Roof insulation stabilises the shed's temperature, reducing condensation risk. This is vital if you’re storing tools or valuables that could be damaged by moisture.

- Increased comfort: Insulation makes your shed more comfortable year-round. Without it, sheds can be too cold in winter and too hot in summer. Proper insulation keeps the temperature consistent, allowing you to enjoy the space for work or hobbies regardless of the weather.

- Energy efficiency: If your shed uses electricity for heating or cooling, insulation helps lower energy consumption. It traps heat in winter and reflects it in summer, reducing the need for constant use of heaters or fans, saving you money on energy bills.

- Protects stored items: Insulation keeps the environment stable inside the shed, which is essential for items sensitive to temperature and moisture changes, such as wooden furniture or electronics. This protection prevents damage caused by extreme heat or cold.

- Extended shed lifespan: Insulating your shed roof reduces moisture and helps regulate temperature, which in turn protects the shed’s structure from wood rot or metal corrosion. This can extend the lifespan of your shed and keep it in good condition for longer.

By investing in shed roof insulation, you improve comfort, protect stored items, and enhance energy efficiency, making your shed a functional space all year.

How to insulate a shed roof

With shed roof insulation, you have two main methods to choose from cold roof insulation and warm roof insulation. Both methods have their advantages, depending on the type of shed you have and how you intend to use it. Here’s a general guide on how to insulate a shed roof, including the key steps and materials involved:

Determine shed usage

Start by deciding how you’ll use the shed. If it’s only for storage, basic insulation may be enough. However, if you plan to use the shed as a workshop, office, or hobby room, you’ll need more effective insulation to maintain a comfortable temperature throughout the year.

Choose insulation

Select the right type of insulation based on factors like your budget, local climate, and the shed’s structure. Common materials include rigid foam boards, mineral wool, and reflective foil. Each has its pros and cons in terms of cost, thermal efficiency, and ease of installation.

Prepare the roof

Before installation, make sure the roof is in good condition—repair any leaks or damage. A roof membrane is essential to act as a moisture barrier, protecting both the insulation and the shed structure. For metal shed roofs, use adhesive to secure the insulation.

Install the insulation

There are two main methods for shed roof insulation:

Cold roof insulation

In this method, the insulation is placed between the rafters, leaving the roof deck itself uninsulated. This is a cost-effective option but requires ventilation to avoid condensation. Key steps include:

- Install a roof membrane: Lay a breathable membrane over the roof deck to protect against moisture.

- Fit insulation panels: Cut insulation panels to fit snugly between rafters, leaving an air gap between roof and insulation for ventilation.

- Secure with adhesive: Ensure the insulation stays in place using adhesive, especially for metal roofs.

- Cover with plasterboard: Once insulated, cover with plasterboard or plywood for a clean finish.

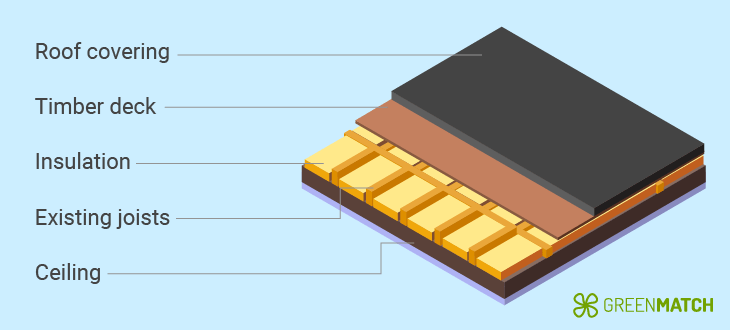

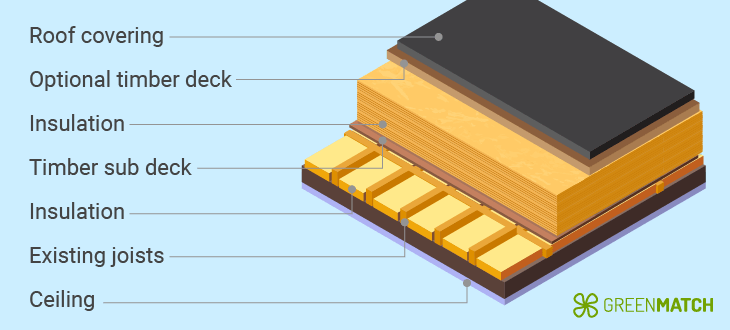

Warm roof insulation

With warm roof insulation, the insulation is installed above the roof deck, creating a continuous layer that keeps the entire roof structure warm and reduces condensation risk. The steps include:

- Lay a vapour barrier: Apply a vapour control layer to prevent internal moisture from reaching the insulation.

- Install rigid insulation boards: Place rigid insulation boards or roof insulation panels on top of the roof deck.

- Add protective sheeting: Secure OSB or plywood on top of the insulation for extra protection.

- Apply waterproofing: Finish with a waterproof membrane to shield the roof from external elements.

Seal gaps and ventilation

After installation, ensure all gaps and seams are sealed using caulk or weatherstripping to prevent air leaks. Additionally, proper ventilation is crucial, especially for cold roof insulation, to prevent condensation buildup. Roof vents can help regulate airflow and maintain the insulation’s effectiveness.

Insulation under roof tiles

For added thermal protection, you can also place insulation under the roof tiles. This creates an extra barrier against heat loss and can be used in both cold and warm roof insulation setups. When paired with a roof membrane and vapour control layers, this method further enhances insulation and moisture protection.

Both cold and warm roof insulation methods are effective, but warm roof insulation is generally better for year-round use due to its superior thermal efficiency. If you’re unsure about which method to use or need help with installation, it’s wise to consult a professional to ensure the best results.

At GreenMatch, we can help you find the best insulation specialists for your shed. Fill out our 30-second form, and we’ll provide up to four free quotes from top experts in your area to help you choose the right insulation method and get your shed properly insulated.

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

Shed roof insulation materials

When considering shed roof insulation, choosing a material that meets your needs in terms of cost, thermal efficiency, and durability is essential. Below are some of the most common insulation materials used for shed roofs, along with their pros, cons, prices, and a recommendation for the best option:

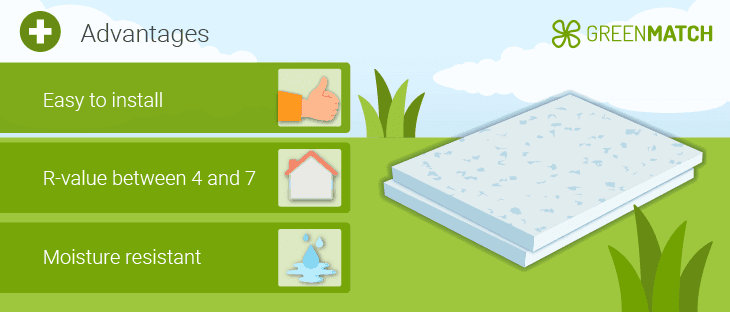

Rigid foam boards

Rigid foam boards, including XPS, EPS, and PIR, are among the best materials for shed roof insulation due to their high thermal efficiency. With R-values between 4 and 7 per inch, they offer superior insulation while being durable and moisture-resistant.

These boards are easy to cut and install, making them popular for DIY projects. However, precise installation is crucial to avoid gaps that could reduce their effectiveness by allowing heat to escape. The downside is that they are more expensive than other options, which can deter budget-conscious users. Costs generally range from £10 to £21.50 per square metre, depending on the type and thickness of the boards, making them a mid- to high-range option for shed insulation.

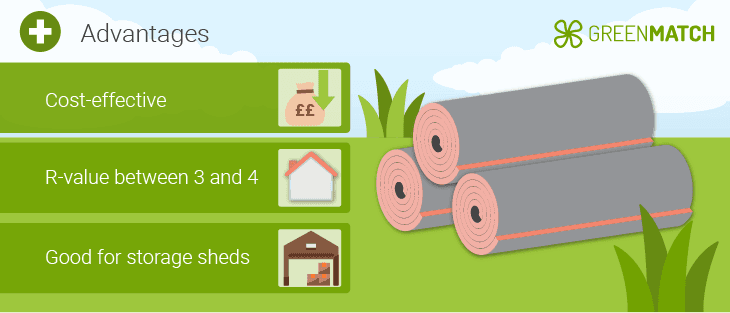

Fibreglass

Fibreglass is one of the cheapest insulation for sheds, making it highly appealing to those on a budget. It offers decent thermal efficiency, with an R-value of 3 to 4 per inch, which is adequate for basic shed insulation needs.

However, fibreglass can absorb moisture, leading to mould growth, especially in wetter climates, reducing its effectiveness over time. Fibreglass requires protective gear during installation, as the small fibres can cause skin irritation and respiratory issues. Despite these drawbacks, fibreglass remains popular due to its low cost, typically around £10 per square metre, making it a good option for sheds primarily for storage rather than as living or workspaces.

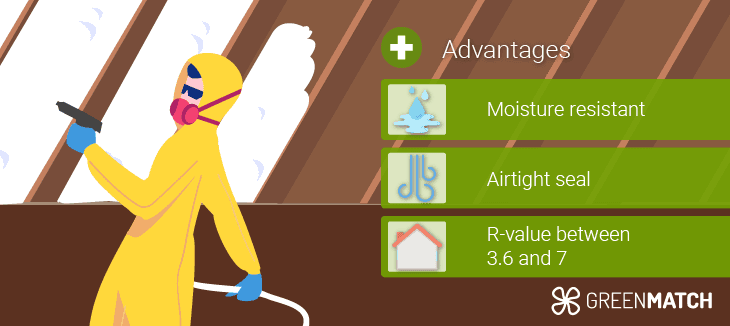

Spray foam

Spray foam insulation is considered one of the best for shed roofs, offering excellent thermal performance with an R-value ranging from 3.6 to 7 per inch. Its ability to expand into gaps and hard-to-reach areas makes it ideal for creating an airtight and moisture-resistant seal, particularly useful in high-usage sheds such as workshops or home offices.

However, the cost is significantly higher than other insulation options, starting at around £21.50 per square metre. Moreover, spray foam requires professional installation due to the need for specialised equipment, which adds to the overall expense. Despite these costs, its superior performance in preventing condensation and maintaining a stable indoor environment makes it a preferred choice for high-efficiency insulation needs.

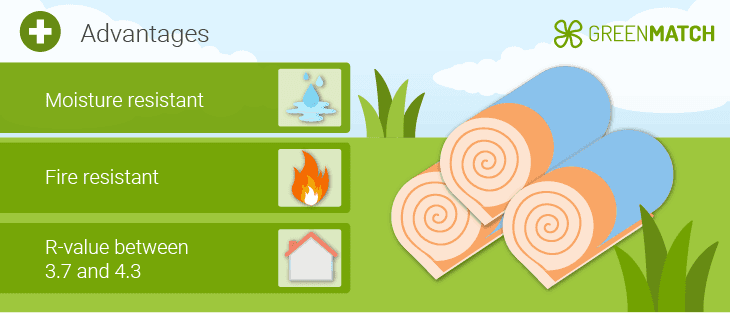

Mineral wool

Mineral wool, including rock wool, is another highly effective option for shed roof insulation, especially in terms of fire resistance. With an R-value between 3.7 and 4.3 per inch, it provides good thermal and sound insulation. Mineral wool is also naturally moisture-resistant, reducing the risk of mould or mildew growth, which can be a concern with other materials like fibreglass.

Its biggest advantage is its fire resistance, withstanding temperatures up to 982°C, making it a safe option for sheds that house flammable materials or tools. However, mineral wool is heavier than other insulation types, which can create structural challenges if not installed correctly. Additionally, it is more expensive than fibreglass, costing between £13 and £17.50 per square metre, but the added benefits of fire and moisture resistance may justify the higher price for some people.

Blown in cellulose

Blown-in cellulose is an eco-friendly insulation material made from recycled paper, which makes it an attractive choice for those looking to reduce their carbon footprint. It offers moderate thermal efficiency, with an R-value between 3.1 and 3.8 per inch. Cellulose is especially effective for insulating hard-to-reach areas in sheds with pitched roofs.

However, it has some drawbacks, including the potential to absorb moisture, which can cause it to sag over time and reduce its insulating ability. A vapour barrier is often required to protect the insulation from moisture damage. Cellulose insulation is also more challenging to install, requiring specialised equipment, making it less suitable for DIY projects. The cost averages around £11 per square metre, placing it in the middle of the price range for insulation materials, balancing sustainability and cost-effectiveness.

The best insulation material for your shed roof depends on your specific needs. Rigid foam boards provide the best overall performance for sheds used as workspaces or living areas due to their thermal efficiency and durability. For budget-conscious users, fibreglass offers adequate performance at a lower cost, though it is more prone to moisture issues.

Spray foam is ideal for maximum efficiency but comes with a higher price tag and requires professional installation. Mineral wool stands out for its fire resistance and moisture control, making it a solid choice for sheds with specific safety concerns. Blown-in cellulose, while eco-friendly, is best suited for those prioritising sustainability but who are willing to manage its moisture sensitivity.

Shed roof insulation cost

The cost of insulating a shed roof depends on factors such as the material used, the size of the shed, and whether you opt for DIY roof insulation installation or hire a professional. Below is the average cost of shed roof insulation based on the size:

| Shed size | Cost |

|---|---|

| 8 x 8 | £670 |

| 10 x 10 | £1005 |

| 16 x 12 | £1600 |

The primary factor influencing cost is the insulation material. Budget-friendly options like fibreglass cost around £10 per m2 but may not offer the same performance as premium materials like spray foam or rigid foam boards, which provide superior thermal efficiency and moisture resistance, making them ideal for sheds used as offices or workshops. The average costs of different materials are as follows:

| Material | Average cost per m2 |

|---|---|

| Fibreglass | £10 |

| Polystyrene (EPS) board | £10 |

| Cellulose | £11 |

| Polyisocyanurate (PIR) board | £12.50 |

| Polyurethane (XPS) board | £21.50 |

| Mineral wool | £13 - 17.50 |

| Spray foam | £21.50 or more |

The method of installation also impacts cost. DIY can save money, especially with more straightforward materials like fibreglass, but professional installation ensures precision, particularly with complex materials like spray foam. Larger sheds and intricate roof designs also increase costs due to the additional material and labour required.

For the best results, it’s advisable to consult a professional who can recommend suitable materials, handle the installation efficiently, and ensure you stay within your budget. By comparing quotes from multiple specialists, you can secure a competitive price. At GreenMatch, we can provide up to four free quotes from top local insulation installers—fill out our 30-second form to get started. No hidden costs, no obligations. Click below to learn more.

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

FAQ

The most common types of insulation for a shed roof include fibreglass, rigid foam boards, spray foam, mineral wool, and blown-in cellulose, with each material offering varying levels of thermal efficiency, moisture resistance, and cost.

Yes, insulating a shed roof is worth it as it improves energy efficiency, prevents condensation, and creates a more comfortable environment, especially if the shed is used as a workshop or office.

To insulate your shed roof, you can install materials like fibreglass, rigid foam boards, or spray foam, ensuring the insulation is properly sealed and protected with a roof membrane or vapour barrier.

Yes, insulating a shed roof can help reduce condensation by regulating temperature differences and preventing moisture build-up, especially when combined with proper ventilation.

Caoimhe is an experienced content writer and researcher who is passionate about providing accessible information to every reader. With a background in English literature and Sociology, she combines the two disciplines to create cohesive, well-thought-out, and well-informed pieces.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?