Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Get Free quotes from insulation specialists near you

Save money by comparing quotes and choosing the most competitive offer

The service is 100% free and with no obligation

- GreenMatch

- Insulation

- Roof Insulation

- Metal Roof Insulation

Metal Roof Insulation: How to Insulate a Corrugated Roof

- Metal roofs are prone to heat transfer and condensation. Insulating them prevents moisture build-up, improves comfort, and extends the roof's lifespan by preventing corrosion.

- Proper insulation can significantly reduce heating and cooling costs, making your building more energy-efficient and lowering long-term utility bills.

- Spray foam is highly effective for corrugated roofs, offering superior thermal resistance and airtight sealing.

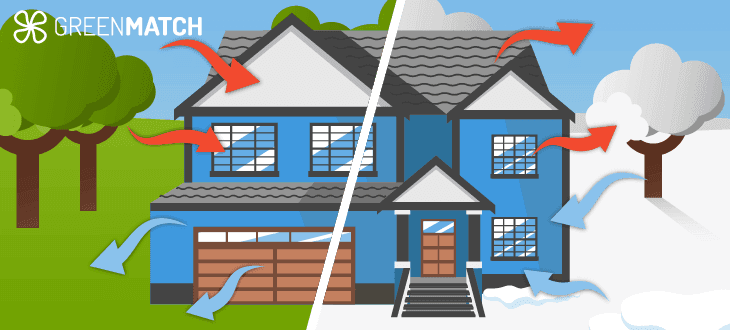

Metal roof insulation is essential to maintaining energy efficiency and comfort in buildings with corrugated metal roofs. These roofs, while durable and long-lasting, can be prone to heat transfer, making the interior of a building hotter in summer and colder in winter.

Corrugated roof insulation helps regulate temperature, reduce energy costs, and minimise condensation, which can lead to corrosion and damage over time. Insulating a metal roof involves selecting the right materials, such as foam boards, fibreglass, or spray foam, and ensuring proper installation to seal gaps and prevent thermal bridging.

This guide will guide you through corrugated insulation, covering the different insulation options, their benefits, and step-by-step instructions on effectively applying them. Whether you're working on garage roof insulation, home or shed roof insulation, proper insulation is critical to improving comfort, energy efficiency, and the roof's lifespan.

Ready to insulate your metal roof with corrugated roof insulation? Finding the right insulation specialist who fits your budget and needs can feel overwhelming, especially when comparing multiple quotes takes time and effort. That's where GreenMatch comes in! We simplify the process by offering up to four free quotes from top corrugated roof insulation experts in your area. Fill out our quick 30-second form, and we'll handle the rest. Click below to learn more!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

Methods for metal roof insulation

There are several effective methods for insulating a corrugated metal roof that offer different benefits depending on the building's needs, climate, and budget. Proper insulation on roofs reduce energy loss, maintain a comfortable indoor environment, and prevent moisture build-up that could lead to corrosion.

Selecting the right insulation method is critical for ensuring the thermal efficiency and longevity of the roof. Below are some standard and effective strategies for insulating a corrugated metal roof, each suited to different situations and needs:

Spray foam insulation

Spray foam is one of the most popular options for corrugated roof insulation due to its versatility, ease of installation, and overall effectiveness. The foam expands to fill cavities, creating an airtight seal, making it ideal for insulating irregular or hard-to-reach spaces.

This is especially useful for corrugated roofs, which are challenging to insulate due to uneven surfaces that leave gaps for air and moisture. Additionally, the metal’s high conductivity easily transfers heat, making proper insulation crucial for energy efficiency. Spray foam addresses these issues by sealing gaps, ensuring consistent insulation coverage, and improving thermal efficiency.

Available in two types—open-cell and closed-cell—spray foam offers varying levels of thermal resistance. Open-cell foam provides an R-value of 3.6 to 3.9 per inch. In contrast, closed-cell foam offers a higher R-value of 6 to 7, delivering better insulation. Once properly installed, spray foam can last up to 100 years, providing long-lasting protection for the roof.

Additionally, spray foam also helps reduce the risk of condensation. Its airtight seal prevents moisture-laden air from reaching the cooler surfaces of the metal roof, where condensation tends to form. This ensures effective moisture control, protecting the roof from potential damage caused by water build up.

In addition to its thermal and moisture control benefits, spray foam significantly reduces noise. Open-cell spray foam is particularly effective at soundproofing, making it ideal for metal roofs notorious for amplifying noise during harsh weather conditions. By dampening sound, spray foam creates a quieter indoor environment. Overall, it is a highly effective solution for corrugated roof insulation, providing comprehensive thermal, moisture, and sound control, ultimately enhancing comfort and improving energy efficiency.

Rigid foam insulation

Rigid foam board insulation is an excellent option for an insulated metal roof, offering high thermal resistance, durability, and ease of installation. Typically made from materials such as expanded polystyrene (EPS), extruded polystyrene (XPS), or polyisocyanurate (PIR), these boards effectively reduce heat transfer, which is crucial for maintaining energy efficiency in buildings with metal roofs.

One of the critical benefits of rigid foam boards is their high R-value, a measure of thermal resistance. Polyisocyanurate boards, for example, have an R-value of 5.6 to 7.0 per inch, making them one of the most efficient options for corrugated roof insulation. Rigid foam board insulation's high thermal efficiency suits both hot and cold climates, regulating indoor temperatures and reducing energy costs.

Rigid foam boards are also easy to install. They are cut to fit between the roof purlins or laid directly over them. This creates a continuous insulation layer that eliminates air gaps. This ensures consistent coverage across the entire roof and prevents heat loss. The rigid structure of the boards helps them retain their shape over time, preventing sagging or compression, which can degrade insulation performance.

In addition to thermal benefits, rigid foam board insulation offers excellent moisture resistance. Many foam boards come with a built-in vapour barrier or are inherently moisture-resistant, helping to prevent condensation on the metal roof. This is particularly important for metal roofs, as condensation can lead to corrosion and long-term damage.

Rigid foam board insulation offers a reliable, cost-effective solution for corrugated roofs, with superior thermal performance and moisture control. Its durability makes it ideal for both residential and commercial buildings.

Fibreglass batts

Corrugated roof insulation commonly uses fibreglass batts for affordability, ease of installation, and effective thermal resistance. Made from fine glass fibres, fibreglass batts are available in pre-cut panels or rolls, making them simple to install between roof purlins or directly under the metal roof.

This insulation method helps reduce heat transfer and enhances energy efficiency in buildings with metal roofs. Fibreglass batts offer a practical, budget-friendly solution for insulating metal roofs, making them popular for residential and commercial applications.

Fibreglass batts offer an R-value of 3 to 4 per inch, providing adequate insulation for most UK climates. Although less effective than spray foam or rigid boards, they are a cost-effective option for areas without extreme temperature concerns.

Fibreglass batts are also relatively simple to install, making them popular for DIY projects. However, to ensure effective corrugated roof insulation, proper installation is critical. Gaps or compressed areas can significantly reduce the material's insulation properties, so cutting the batts precisely and fitting them snugly between the roof framing is essential. Additionally, the material is dangerous to handle. Therefore, protective gear is required to prevent skin irritation or respiratory issues.

Fibreglass batts offer good thermal resistance but lack a vapor barrier, requiring a vapor control layer to prevent moisture build-up. This is particularly important for metal roofs, as condensation can lead to rust and corrosion over time.

Corrugated roof foam fillers

Corrugated roof foam fillers are essential components in metal roofing systems, designed to provide an effective seal between the corrugated metal sheets and other structural elements. These foam fillers are custom-shaped to fit corrugated sheets, filling gaps created by the ridges and valleys of the roof. They are crucial for corrugated roof insulation, preventing air, water, dust, and insects from entering the building.

Foam fillers not only seal gaps but also improve insulation by blocking unwanted airflow. They are often used with insulation materials like spray foam, fiberglass batts, or rigid foam boards. When combined, foam fillers help create a more airtight, energy-efficient roofing system by sealing gaps other insulation may miss.

Typically made from polyurethane, foam fillers offer flexibility and resilience. They create a tight seal that reduces drafts and improves thermal efficiency, contributing to better temperature regulation inside the building. Additionally, foam fillers help prevent condensation from forming underneath the metal roof, which can otherwise lead to rust and corrosion over time.

Corrugated roof foam fillers are also easy to install. They are placed under the corrugated sheets or along the roofline where gaps occur. Available in various sizes and profiles, foam fillers are designed to fit snugly with the specific corrugated pattern of the metal roof, ensuring a seamless seal.

How to insulate a corrugated roof

Proper corrugated roof insulation is crucial for maintaining energy efficiency, preventing condensation, and ensuring the long-term durability of your structure. Follow these simple steps to insulate a corrugated roof effectively:

- Assess the roof: Inspect the roof for leaks, gaps, or structural issues. Make any necessary repairs, addressing rust or corrosion to avoid future problems.

- Choose the insulation material: Select insulation based on your climate and budget. Popular options include fibreglass batts, spray foam, or rigid foam boards.

- Install foam fillers: Place corrugated foam fillers between the ridges and valleys of the roof to seal gaps. This ensures a tight seal that prevents drafts, water ingress, and pests.

- Install a vapour barrier: Add a vapour barrier under the roof before applying insulation. This prevents moisture from entering the insulation, reducing the risk of condensation buildup.

- Apply the insulation: Cut the insulation to fit snugly between roof purlins or apply it directly to the underside. Fibreglass batts should be placed without gaps, while spray foam can be evenly applied across the surface. For rigid foam boards, cut them to size and place them over the vapour barrier.

- Seal gaps: Ensure all gaps around the insulation are sealed with foam fillers or caulking. This step is essential for preventing air leaks and maintaining a moisture-free environment.

- Prevent condensation: Minimise condensation by ensuring proper ventilation with ridge vents or soffit vents, allowing air to circulate and prevent moisture buildup.

- Inspect the insulation: Inspect the insulation to ensure it's properly fitted, with no sagging or gaps. Check that the vapour barrier is intact.

Ready to improve your roof's energy efficiency? Fill out GreenMatch's 30-second form to receive up to four free quotes from top insulation specialists. No obligations, no hidden costs—just the best solutions for your corrugated roof insulation needs!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

Best metal roof insulation materials

When selecting the best insulation for roofs, it’s essential to consider factors like efficiency, cost, and sustainability. Here are the three best insulation materials for corrugated roof insulation, each excelling in a different category.

Most thermally effective

Spray foam insulation is the most effective option for corrugated roof insulation. It offers excellent thermal resistance with an R-value of 6 to 7 per inch for closed-cell foam. It creates an airtight seal, prevents drafts and condensation, and expands to fill hard-to-reach spaces for full coverage.

Spray foam is one of the most expensive insulation materials, with costs starting around £21.50 per m². Prices can vary depending on whether you choose closed-cell or open-cell foam. While highly durable—lasting up to 100 years with proper maintenance—spray foam is not considered the most sustainable option. It is made from petroleum-based chemicals and may contain hydrofluorocarbons (HFCs), which can emit greenhouse gases, making it less eco-friendly than other insulation materials.

Most cost-effective

Fibreglass is the most cost-effective option for corrugated roof insulation, with a typical price of around £10 per m2, making it an excellent choice for budget-conscious projects. While affordable, fibreglass has a lower R-value than other insulation materials, usually ranging between 3 to 4 per inch, providing moderate thermal resistance. When combined with a vapour barrier, fibreglass can still offer effective insulation for corrugated roofs, though it doesn’t match the efficiency of foam-based options.

Fibreglass can be considered a sustainable choice, as it is made from recycled materials like glass and sand. However, manufacturing is energy-intensive, melting silica sand and other raw materials at high temperatures to create glass fibres. According to the International Energy Agency (IEA), the glass manufacturing industry, including fibreglass production, contributes to about 0.5% of global CO2 emissions.

Most sustainable

Rigid foam boards, particularly PIR boards, are the most sustainable for roof insulation sheets available. PIR boards generate less waste during production and can be recycled, making them an eco-friendly option. After their lifespan in a building, they can be repurposed or recycled, preventing them from ending up in landfills and reducing overall waste.

PIR boards are also highly durable, with an average lifespan of up to 50 years, minimising the need for frequent replacements. This longevity further enhances their sustainability. In addition to their durability, PIR boards provide high R-values ranging from 5.6 to 7 per inch, offering excellent thermal resistance and moisture control. This makes them a reliable and efficient choice for corrugated roof insulation.

Cost-wise, PIR boards are also a good investment, typically priced around £12.50 per m2, striking a balance between cost, efficiency, and sustainability. With their durability, thermal performance, and eco-friendly features, PIR boards are a solid all-around option for insulating metal roofs.

It’s essential to consult with insulation specialists to ensure you choose the best material for your corrugated roof. They will customise the solution to fit your needs, preferences, and budget. At GreenMatch UK, we can connect you with top insulation experts in your area. Fill out our quick 30-second form, and you’ll receive up to four free quotes from trusted professionals. Click below to learn more.

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

Is corrugated roof insulation worth it?

Corrugated roof insulation is worth it for various reasons, including sustainability, energy savings, and cost reduction. Proper insulation improves the thermal efficiency of your building by reducing heat transfer keeping your space cooler in summer and warmer in winter. This leads to significant energy savings, decreasing the need for heating and cooling and ultimately lowering your energy bills.

Over time, these savings can more than offset the initial corrugated insulation cost. Metal roof insulation also enhances the sustainability of your building by reducing its carbon footprint. Many insulation materials, like PIR boards and fibreglass, are made from or can be recycled, helping to reduce waste. In addition to energy efficiency, a well insulated metal roof protects against condensation and moisture build up, extending the lifespan of your roof and preventing costly repairs.

To fully reap the benefits of insulated corrugated roofing, it's recommended to have a professional installation to ensure compliance with roof insulation regulations and optimal performance. Professionals can ensure your insulation is installed correctly, following regulations such as U-value requirements for energy efficiency.

Finding the right insulation specialist that fits your needs and budget can be time-consuming. You might spend hours comparing quotes with little success. Luckily, GreenMatch makes it easy. Fill out our 30-second form, and we'll provide up to four free quotes from top insulation specialists—no obligations, no hidden costs. Click below to get started and learn more!

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds

FAQ

Yes, you can insulate a corrugated roof using various materials like spray foam, fibreglass batts, or rigid foam boards to improve thermal efficiency and reduce energy costs.

Yes, you can put insulation directly under a metal roof, but it is important to use a vapour barrier and ensure proper ventilation to prevent moisture build up and condensation.

The best insulation for a corrugated roof is spray foam, as it provides excellent thermal resistance, fills gaps completely, and creates an airtight seal, though rigid foam boards and fibreglass batts are also effective options depending on budget and needs.

To stop condensation on a corrugated roof, ensure proper ventilation, use insulation with a vapour barrier, and seal any gaps to prevent moisture-laden air from reaching the cooler roof surface.

Yes, you should use a vapour barrier under a metal roof to prevent moisture build up and condensation, which can lead to rust and damage over time.

Caoimhe is an experienced content writer and researcher who is passionate about providing accessible information to every reader. With a background in English literature and Sociology, she combines the two disciplines to create cohesive, well-thought-out, and well-informed pieces.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?

- Describe your needs

- Get free quotes

- Choose the best offer

It only takes 30 seconds