- GreenMatch

- Boilers

- Boiler Pressure

Understanding Boiler Pressure: Troubleshooting and Maintenance Tips

Boilers are essential for keeping our homes warm and cosy, but ensuring they operate at optimal pressure is equally vital. Boiler pressure is like its heartbeat, indicating the health and functionality of your heating system.

Maintaining optimal pressure ensures efficient operation and prevents costly breakdowns and boiler replacement.

Understanding boiler pressure is no rocket science. This comprehensive guide educates homeowners and others about maintaining the right boiler pressure, troubleshooting common issues, and adopting best practices for effective boiler maintenance.

Understanding optimal boiler pressure

Put simply, boiler pressure is the force exerted by the heated water inside your boiler and heating system.

Since the primary function of any boiler is to warm up water and run it through a heating system, boiler pressure ensures sufficient water circulation, prevents airlocks, and ensures the proper functioning of pumps, valves and expansion vessels.

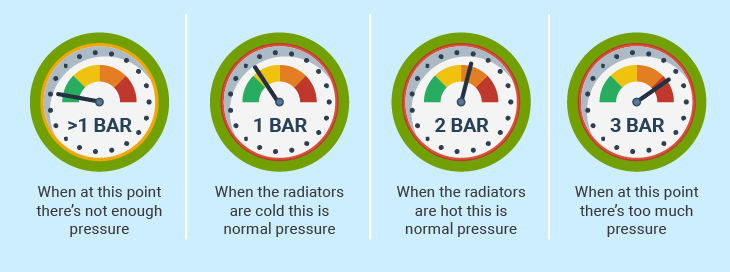

Generally, most residential boilers operate within a 1.0 to 2.0 bar pressure range. Therefore, this is considered a normal pressure range for the most adequate heating.

Commercial boilers have higher pressure requirements and operate within the 2.0 to 3.0 and even higher pressure range.

The ideal range may vary depending on your specific model, so refer to your boiler manual for its recommended pressure.

Before we discuss the abnormal boiler pressure, let's quickly break down why keeping your boiler pressure in optimal conditions is crucial.

Why optimal boiler pressure is important

Boiler pressure is easy to track, yet it isn't something you should completely neglect. Here's how a healthy boiler pressure influences your boiler's operation:

- Efficiency: inadequate boiler pressure leads to inefficient heat transfer. Optimal pressure ensures that water or steam can circulate through the heating system and distribute heat to radiators.

- System functionality: A balanced and effective heating distribution is only possible with correct boiler pressure.

- Safety: Operating beyond the recommended pressure can lead to leaks or boiler failures.

- Longevity: Regular monitoring and maintaining optimal pressure reduces the likelihood of premature breakdowns.

Let's look closer at why boiler pressure can fall below or exceed the optimal range and what usually stands behind that.

Reasons for high and low boiler pressure

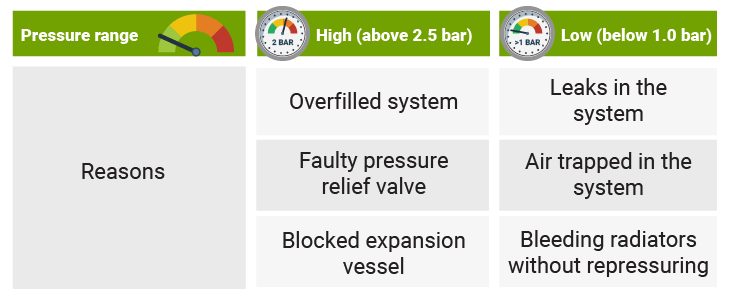

High pressure (above 2.5 bar): This can be dangerous and trigger safety shutdowns. It can be caused by:

- Overfilling the system: The filling loop adds water to the heating system. If its check valve doesn't close properly or is poorly adjusted, water can eventually enter continually and overfill the loop.

- Faulty pressure relief valve (PRV): This valve malfunctions and does not release excess pressure. When the valve malfunctions, it fails to open as intended, hindering the system's ability to relieve pressure. Without proper relief, the system becomes fragile before overpressurisation.

- Blocked expansion vessel: This component absorbs pressure fluctuations, and a blockage can cause pressure buildup. If waterlogged, it fails to provide needed buffer space for expanding water during heating cycles. This increases the pressure and leads to potentially hazardous situations.

Low pressure (below 1.0 bar) can compromise heating performance and boiler efficiency. It can be caused by:

- Leaks in the system: Because of the leaks, the pressure decreases due to the reduced volume of water in the system. Besides decreased pressure, leaks pose risks of water damage to surrounding structures and boiler inefficiency.

- Air trapped in the system: Air pockets can prevent proper water circulation and reduce pressure. Inadequate bleeding can trap air in radiators or pipes, impacting system pressure. Trapped air reduces the effective water volume within the system, resulting in uneven heating.

- Faulty filling loop: The filling loop is responsible for adding water to the heating system. If its check valve doesn't close properly or is poorly adjusted, water can eventually enter continually and overfill the loop. This valve is used to top up water; a malfunction can prevent proper filling.

How to check boiler pressure

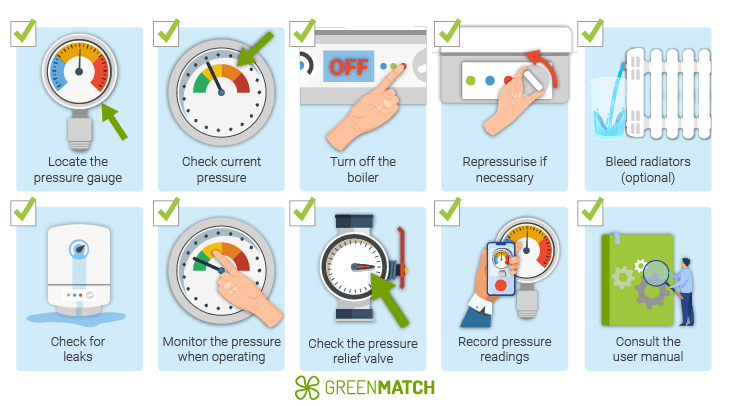

Checking boiler pressure is a straightforward process that can be done by following these steps:

- Locate the pressure gauge: The pressure gauge is typically located on the boiler's front panel. It resembles a small dial or a digital display and is usually marked in bar units.

- Check current pressure: Observe the current pressure reading on the gauge. The ideal pressure for most boilers is between 1.0 and 2.0 bar when the system is cold.

- Turn off the boiler: To get an accurate reading, ensure that the boiler is turned off and has had sufficient time to cool down.

- Repressurise if necessary: If the pressure is below the recommended range, you may need to repressurise the system. Refer to your boiler's user manual for specific instructions on how to do this. It often involves using a filling loop to add water to the system until the desired pressure is reached.

- Bleed radiators (optional): If you have recently bled radiators, repressurise the system afterwards. Bleeding releases air, which can cause a pressure drop.

- Check for leaks: While checking the pressure, take the opportunity to inspect the boiler and surrounding pipes for any signs of water leaks. Leaks can contribute to pressure fluctuations.

- Monitor the pressure when operating: Turn on the boiler and observe the pressure gauge while the system runs. The pressure may increase slightly when the boiler operates, but it should remain within the acceptable range.

- Check the pressure relief valve: Ensure that the pressure relief valve is functioning correctly. If there are any signs of water discharge from the overflow pipe or the valve leaking, it may indicate a problem that needs attention.

- Record pressure readings: Record your boiler's pressure readings over time. This can help you identify any patterns or irregularities and provide useful information for maintenance.

- Consult the user manual: Refer to the boiler's manual for specific instructions and recommendations regarding pressure levels, bleeding, and repressurising.

Boiler Leaking Water

Boiler leaks can disrupt your comfort and lead to significant damage if not addressed promptly. Homeowners and facility managers must understand the common causes and fixes for boiler leaks.

In the UK, the average cost of repairing a leaking boiler ranges from £100 to £500, depending on the issue's complexity. Regular maintenance checks prevent these unexpected costs and ensure your boiler operates efficiently.

Ignoring a leaking boiler can lead to increased repair costs and even replacement. Early detection and repair can save money and extend the life of your boiler.

| Repair Type | Average Cost (£) |

|---|---|

| Minor Leak Repair | £100 - £200 |

| Major Component Fix | £200 - £500 |

| Complete Replacement | £1,000 - £2,500 |

Troubleshooting common boiler pressure problems

Systematically check for the following factors to identify the root cause of the problem.

Pressure fluctuations

Fluctuations in boiler pressure can result from various issues, such as air trapped in the system, faulty pressure relief valves or water leaks.

Air trapped in the system can be released through bleeding, while a malfunctioning pressure relief valve or water leaks require detailed inspections and potential replacements.

Sudden pressure drops

Sudden pressure drops may indicate water loss due to leaks or bleeding radiators without subsequent repressurisation. Examine the system for visible leaks and ensure proper repressurisation after bleeding.

Identifying and addressing leaks promptly is crucial to prevent further water loss. Repressuring the system after bleeding radiators ensured a balanced and stable pressure.

Constantly high pressure

A high-pressure situation may arise from a malfunctioning pressure relief valve, waterlogged expansion vessel, or issues with the filling loop. Investigate each point to pinpoint the cause.

Addressing a faulty pressure relief valve, draining and repressurising the expansion vessel, and inspecting the filling loop for malfunctions are important steps to resolve high-pressure issues.

The procedure of repressurising is almost the same for various boiler types; you can do it yourself in a few minutes. The process includes attaching the filling loop, opening and closing the valves and removing the filling loop.

If you need more clarification about repressurising your boiler, please call a Gas-safe engineer to help you.

Maintenance tips for optimal boiler pressure

Regular system inspections

Routine inspections help identify potential problems before they escalate, contributing to proactive maintenance and optimal pressure control.

At least once a month, conduct thorough visual inspections of the entire heating system, including valves, pipes, and radiators, to detect any signs of leaks or malfunctions.

Proper bleeding procedures

Bleeding radiators is a common maintenance task. Ensure that bleeding is accompanied by repressurisation to maintain the overall water volume in the system.

Bleeding without repressurisation can lead to low pressure. Implementing the correct procedure ensures a balanced system and prevents pressure-related problems.

To bleed a radiator, you will need a radiator bleed key, a cloth, an old towel, and a container. Turn off your heating and wait till the radiators cool down. Carefully insert and turn the radiator key anti-clockwise until you hear a hissing noise. Close the valve once the water starts to flow out.

Expansion vessel checks

Regularly check the expansion vessel for signs of waterlogging, ensuring it has the necessary air cushion to accommodate water expansion during heating cycles.

A waterlogged expansion vessel compromises its ability to absorb excess water, contributing to pressure irregularities. Regular checks prevent this issue.

Advanced considerations

The tips mentioned above are DIY-friendly and can be resolved by yourself. However, there are solutions to faulty boiler pressure that require a certain level of technical knowledge and expertise.

1. Filling loop calibration: Calibrate the filling loop valves to ensure accurate control over water entry. Adjustments should be precise to prevent overfilling or insufficient water intake.

Proper filling loop calibration is crucial for maintaining optimal pressure levels. Precise adjustments contribute to a well-balanced heating system.

Understanding the correct calibration during regular, combi or system boiler installation is crucial for its long-term efficiency.

2. Pressure relief valve calibration: Calibrate the valve to ensure it opens and closes at the correct pressure thresholds, preventing overpressurisation and pressure drops.

A well-calibrated pressure relief valve is a critical safety feature. Regular checks and adjustments contribute to effective pressure management.

3. System retrofitting for efficiency: Consider advanced system retrofitting options, such as installing smart controls or upgrading components for enhanced efficiency and pressure regulation.

Modernising the heating system can improve pressure control, energy efficiency, and overall performance, especially in older boiler systems.

Understanding and maintaining optimal boiler pressure is paramount for efficient and safe heating system operation.

All in all, whether you're addressing high or low-pressure issues, regular system inspections, proper bleeding procedures, and checks on critical components contribute to the longevity and performance of your boiler.

FAQ

The ideal boiler pressure varies depending on the type of boiler and its intended use, but it is typically between 1.0 and 2.0 bar for residential boilers.

You should check boiler pressure regularly, at least once a month. This way, you will ensure the pressure is within the recommended range.

If the boiler pressure is too high, it increases the risk of leaks, bursts or a complete boiler breakdown.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?