- GreenMatch

- Blog

- Is Polymer Clay Bad for the Environment? Stats, Trends, and Facts

Polymer Clay: A Green Analysis of Its Environmental Footprint

Polymer clay, a mix of polyvinyl chloride (PVC), pigments and a plasticiser derived from salt and oil, is at the forefront of crafting and modelling hobbies worldwide. Its versatility and ease of use have made it a favourite among hobbyists and professionals.

As this unique material finds its place, from modelling clay for kids to intricate art pieces, questions surrounding its environmental footprint grow louder.

The health implications of working also warrant attention. Although the use of certain harmful phthalates has been banned in the EU and the USA, residual health risks remain for those frequently handling the material.

Despite environmental concerns, the market is experiencing growth, particularly in emerging markets like Asia Pacific and Latin America. This growth is attributed to rising disposable incomes and the popularity of creative hobbies.

We delve into the green analysis of polymer clay, examining if it is environmentally friendly, biodegradable, or detrimental to our planet. This article explores every corner of polymer clay's environmental footprint, from its production to its sustainability, and offers alternatives that pave the way for a greener future in crafting.

What Is Polymer Clay?

Polymer clay is a versatile crafting material primarily composed of polyvinyl chloride (PVC) and a plasticiser, which makes it malleable and easy to shape before it is cured. It is synthetic, unlike traditional clay, containing natural minerals.

This accessibility makes it a popular choice for artists and hobbyists to create various decorative and functional items such as jewellery, sculptures, and home decor.

The material is available in many colours and effects, including translucent, metallic, and stone-like finishes. Users can mix different colours or add materials like glitters and mica powders to achieve various aesthetics.

Originally formulated as a potential replacement for Bakelite, polymer clay was popularised in art when German doll maker Käthe Kruse began using it in 1939 under the name "FIMO."

Composition and Properties

Polymer clay's unique properties are derived from its two main components:

- PVC (Polyvinyl Chloride): This synthetic polymer provides the structural backbone of the clay.

- Plasticisers: These are added to the PVC to make the clay flexible and workable. Earlier formulations included phthalates, but modern polymer clays use safer alternatives due to health concerns.

Curing Process

It cures at relatively low temperatures ranging from 265 °F to 275 °F (129 °C to 135 °C). The curing process typically takes about 15 minutes per 1/4 inch of thickness, making it suitable for home ovens. This accessibility in curing allows enthusiasts and professionals alike to create intricate designs without the need for industrial kilns.

Polymer Clay vs Other Clays

Polymer clay primarily comprises polyvinyl chloride (PVC), significantly differentiating it from other clays like air-dry and ceramic variants. Air-dry clay, as the name suggests, hardens upon exposure to air and generally has a lighter, spongier texture. Ceramic clay, on the other hand, requires kiln firing at high temperatures to cure.

Here’s a brief comparison of polymer clay with other popular types of clay:

| Type of Clay | Composition | Curing Method | Texture | Colour Options | Environmental Impact |

|---|---|---|---|---|---|

| Polymer Clay | PVC-based | Oven-baked | Pliable | Extensive | High (due to PVC content) |

| Air-Dry Clay | Paper/Cellulose | Air-dried | Spongy | Limited | Low |

| Ceramic Clay | Natural clay | Kiln-fired | Grainy | Glazes/Stains | Moderate |

The Environmental Impact of Polymer Clay

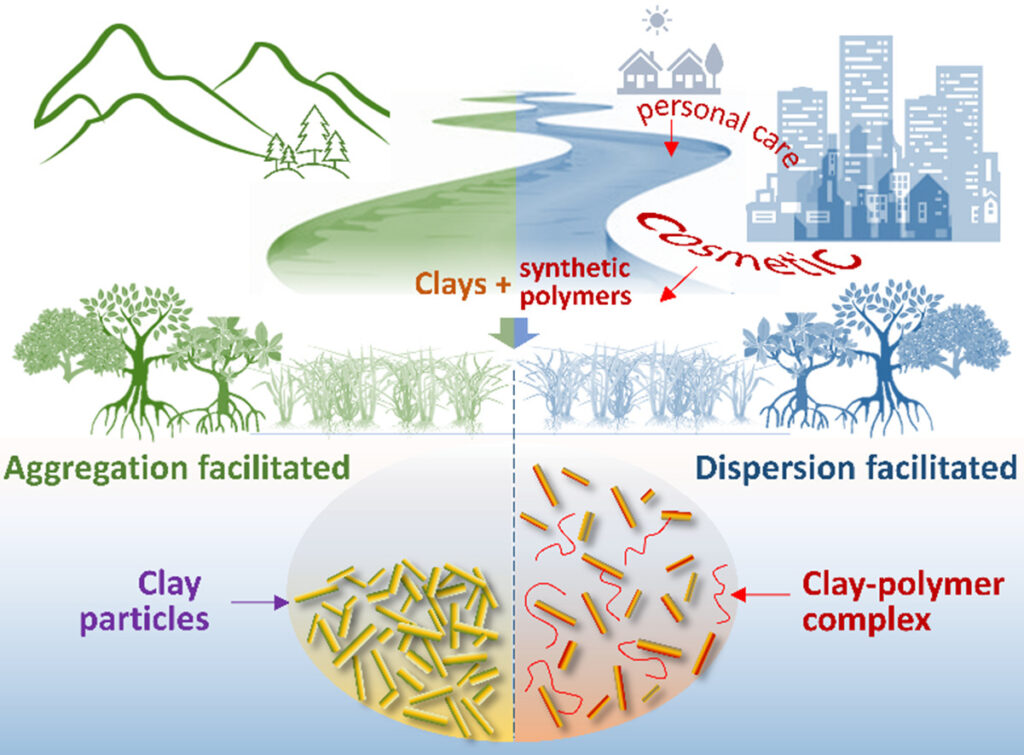

PVC is a synthetic polymer derived from non-renewable resources such as petroleum or natural gas, making the production of polymer clay heavily dependent on fossil fuels. This reliance contributes to significant carbon emissions during both the manufacturing and disposal stages of the product's life cycle.

Image Credit: Science Direct

Notably, PVC is not biodegradable and can leach harmful chemicals, complicating waste management and recycling efforts. Approximately 40 million tonnes of PVC are produced annually, with polymer clay making up a tiny fraction. Despite its minor share, the environmental implications of its use and disposal are significant.

What is the impact of Polymer Clay?

The impact extends from its production to its disposal:

- Production: The creation of PVC, the base component of polymer clay, involves toxic chemicals that can harm the environment. Chlorine production, a critical step in making PVC, releases dioxins, potent carcinogens.

- Usage: Crafters are exposed to phthalates, chemicals used to soften polymer clay, linked to health issues like reproductive problems and nerve system damage.

- Disposal: Polymer clay items, if not recycled, end up in landfills or the ocean, contributing to plastic pollution. The breakdown of PVC releases harmful chemicals, further contaminating ecosystems.

Total Impact per Year

Globally, the market was valued at £22.6 million in 2021 and is projected to reach £29.5 million by 2030. This growth indicates an increasing use, exacerbating its environmental impact.

Impact per Day

Countless projects are created, used, and eventually discarded daily, adding to the ever-increasing plastic pollution problem. Crafting and disposal contribute to the accumulation of PVC in the environment, with long-term degradation releasing toxic substances.

Impact per Usage

Each use, from crafting to disposal, adds to the environmental burden. The production of a single polymer clay item involves the emission of greenhouse gases and potentially exposes users to harmful chemicals.

The following table summarises critical points regarding the environmental impact:

| Aspect | Impact |

|---|---|

| Biodegradability | Polymer clay is not biodegradable, complicating disposal and recycling efforts. |

| Chemical Leaching | It can leach harmful chemicals, mainly when disposed of improperly. |

| Dioxin Release | Burning polymer clay can release dioxins, potent environmental pollutants. |

| Micro Particles | Sanding releases microparticles that may harm aquatic environments. |

| Global PVC Production | Polymer clay is a small part of global PVC production but poses significant environmental challenges. |

| Recycling Challenges | Difficult to recycle (9-10%) due to additives and fillers that need to be separated. |

Polymer Clay Top Producing Countries

This popular crafting material has the highest production volumes from various countries, each contributing significantly to the global supply. These countries host major companies like Staedtler Mars, Polyform Products, Van Aken International, Polyform Products and American Art Clay, driving innovation and distribution in the industry.

The following table provides a detailed look at the distribution of polymer clay shipments across key producing countries:

| Country | Shipments |

|---|---|

| China | 830 |

| Indonesia | 443 |

| United States | 397 |

| India | 337 |

| Thailand | 64 |

| Belgium | 53 |

| Germany | 52 |

| South Korea | 22 |

| Japan | 16 |

| United Kingdom | 15 |

| Other Countries | Various |

Here, we explore the leading nations in production, characterised by the number of shipments they dispatch annually, highlighting their pivotal role in the market.

Leading Producers

China

At the forefront, China dominates the polymer clay market with a substantial 830 shipments annually. This high volume underscores China's significant manufacturing capabilities and central role in supplying global markets.

Indonesia

Following China, Indonesia ranks the second-largest producer, contributing 443 shipments yearly. Indonesia's robust production figures reflect its growing influence in the industry.

United States

The United States holds the third position with 397 polymer clay shipments annually. This shows the US's strong production capacity and large domestic product market.

India

India stands fourth, with 337 shipments, indicating a solid manufacturing base and a rising presence in the sector.

Thailand

Thailand rounds out the top five, dispatching 64 shipments each year. While smaller in volume than the leaders, Thailand's contribution is crucial to the regional supply chain.

Other Notable Producers

Several other countries also play key roles in the production of polymer clay. Belgium, Germany, South Korea, Japan, and the United Kingdom have production figures ranging from 15 to 53 shipments annually. While not matching the output of the top producers, these countries are significant players in the European and Asian markets.

Statistics, Facts and Figures About Polymer Clay

It has gained popularity worldwide due to its ease of use and flexibility in creating various decorative and functional items. However, its environmental impact, production, and usage statistics reveal a complex picture that varies significantly across different regions.

Let's delve into the fascinating world of polymer clay by the numbers.

Market Size

- The polymer clay market has been experiencing steady growth, with projections indicating a rise from £24.34 million in 2022 to an estimated £33.27 million by 2030, marking a compound annual growth rate (CAGR) of 4%.

- The United States leads in market size growth and is expected to expand at a compound annual growth rate (CAGR) through the forecast period.

Usage Statistics by Region

- North America: Dominates the polymer clay market with innovative uses in both residential and commercial sectors.

- Europe: Germany, the UK, and France are significant users, strongly focusing on eco-friendly alternatives due to stringent EU regulations. It shows a growing trend towards sustainable materials, yet it remains popular for educational and professional applications.

- Asia-Pacific: Rapidly expanding market with increasing demand for customised polymer clay items, driven by rising disposable incomes and changing consumer preferences.

| Region | Annual Production (Tonnes) | Yearly Consumption (Tonnes) | Environmental Impact Score |

|---|---|---|---|

| Europe | 20,000 | 18,000 | High (Chemical pollutants, PVC) |

| North America | 15,000 | 14,000 | Moderate (PVC waste, microplastics) |

| Asia-Pacific | 10,000 | 12,000 | Rising (High energy consumption, PVC) |

| Rest of the World | 5,000 | 6,000 | Low (microplastics) |

Environmental Impact

- The production of PVC not only consumes fossil fuels but also releases dioxins, a group of toxic chemical compounds that can persist in the environment.

- Polymer clay items are non-biodegradable, contributing to long-term waste in landfills.

- The world generates around 350 million tonnes annually, with a substantial portion needing to be effectively managed or recycled.

- Polystyrene, for example, is notably resistant to biodegradation due to its chemical structure.

- It contributes to around 86% of plastic emissions in the ocean.

Polymer Clay Brands

Brands of polymer clay include Cernit, Oytra, Fimo, Kato Polyclay, Sculpey, PVClay Brasil, Crafty Argentina, and Cosclay.

- Residential applications dominated the market, capturing over 50% of the share.

- In 2021, solid polymer clay accounted for the largest market share globally.

- Recycling polymer clay remains challenging due to the difficulty of separating its additives and sorting different plastic types.

- Polymer clay is a tiny proportion of all PVC produced globally, at about 40 million tonnes annually.

- PVC, the primary component of polymer clay, accounts for about 20% of all plastic manufactured worldwide, making it the third-most widely produced synthetic plastic polymer.

Is Polymer Clay Toxic?

The most significant concern involves the fumes released during baking. When it is overheated, it can produce fumes containing hydrochloric acid and other toxic substances. These fumes can irritate the eyes, throat, and lungs, and prolonged exposure can lead to more severe health issues.

There is also a risk of inhaling microscopic particles if the clay is sanded or drilled without proper protection.

However, the good news is that significant brands try to follow the safe recommended guidelines. These clays have been tested and certified to be non-toxic.

However, there are some key things to keep in mind:

-

Safe Use is Key: Like many materials, following proper handling techniques is essential. This includes using separate tools for clay and food, washing hands thoroughly after use, and avoiding inhalation of dust from sanding or buffing cured clay.

-

Burning is Bad: Overheating or burning polymer clay is where safety concerns arise. When burnt, the clay can release irritating fumes or vapours. Following the recommended baking temperatures and avoiding overheating will prevent this. If accidental burning occurs, ventilate the area immediately.

- Not Food-Safe: While cured polymer clay is inert, it can be porous. This means it's not recommended for use with food or drink as it can harbour bacteria.

Is Polymer Clay Biodegradable?

Unlike natural clay, polymer clay does not biodegrade. Once baked, it can last for years without breaking down, contributing to plastic pollution.

The main issue with non-biodegradable polymer clay is the potential for leaching chemical additives like phthalate plasticisers, which are linked to health concerns like reproductive issues and developmental disorders. While certain phthalates have been banned in polymer clays sold in the US and EU, there are still residual worries about the safety of working with these materials.

Furthermore, it cannot be recycled through conventional municipal recycling programs. This lack of biodegradability and recyclability means that the products if discarded, contribute to the volume of permanent waste in landfills.

Can it be Sustainable?

Despite the challenges, there are steps to mitigate the environmental impact. The practices within the community, such as recycling and repurposing, contribute positively towards sustainability goals.

However, its sustainability is a concern due to its PVC content, reliance on fossil fuels, and the challenges associated with disposal.

Environmental Impact Compared to Everyday Things

To understand the environmental impact, comparing it with everyday items commonly used and disposed of in similar quantities is essential. This comparison provides a clearer picture of where polymer clay stands regarding sustainability.

We must first examine common items' CO2 levels to understand polymer clay's impact.

| Item | CO2 Emissions (kg CO2 per kg) |

|---|---|

| Polymer Clay | 1.9 |

| Cotton T-shirt | 2.1 |

| Plastic Water Bottle | 6.0 |

| Smartphone | 55.0 |

| Beef (per kg) | 60.0 |

This table reveals that while not negligible, its environmental impact pales compared to items like smartphones and beef. For instance, while polymer clay emits 1.9 kg of CO2 per kg, everyday items like plastic bottles generate significantly higher emissions—up to 6.0 kg of CO2 per kg.

It's crucial to note that these figures offer a global perspective, highlighting our broader environmental challenges.

What Are Alternatives to Polymer Clay

Exploring eco-friendly alternatives is essential for those looking to reduce their environmental footprint while engaging in creative endeavours. Here, we present various substitutes catering to different needs and preferences, ensuring everyone can find a suitable option.

Eco-Friendly Alternatives to Polymer Clay

- Air-Dry Clay: Unlike polymer clay, air-dry clay does not require baking in an oven. It hardens at room temperature, making it a safer and more energy-efficient option. Air-dry clay is also lighter, which can be advantageous for larger projects.

- Paper Clay: Made from natural fibres, paper clay is biodegradable and non-toxic. It's an excellent choice for artists and educators who are conscious of the environmental impact of their materials. Paper clay can be fired in a kiln, but it also air-dries solidly, offering flexibility in its use.

- Homemade Clay: You can make clay at home using cornstarch, white glue, and lemon juice. This DIY approach allows complete control over the materials, ensuring they are non-toxic and environmentally friendly. Homemade clays often mimic the texture and workability of polymer clay.

- Natural Clay: Extracted directly from the earth, natural clay can be fired in a kiln to create durable ceramic pieces. This type of clay is ideal for artistic and functional items, and it does not contain synthetic materials, making it a sustainable choice.

- Cold Porcelain: This DIY alternative mixes cornstarch and glue, offering a non-toxic, inexpensive option, albeit a bit tricky to work with due to its tackiness

- Recycled Paper Beads: For jewellery makers, recycled paper beads provide a creative and eco-friendly alternative to polymer clay beads. These beads are made from upcycled paper, reducing waste and avoiding the use of plastics.

Is Polymer Clay Better Than Its Alternatives?

While polymer clay offers unmatched versatility and durability, it is not eco-friendly or biodegradable. The alternatives mentioned above are more sustainable and have a lower environmental impact.

For instance, air-dry and paper clays offer similar workability without baking, reducing energy consumption and eliminating the release of potentially harmful fumes. Homemade and natural clays support sustainability by utilising non-toxic, biodegradable materials.

Moreover, using recycled paper beads highlights the creative reuse of materials that might otherwise contribute to waste. Each alternative has unique properties and uses, making them comparable to polymer clay and, in many cases, a better choice for the planet and personal health.

| Alternative | Eco-Friendly | Biodegradable | Durability | Cost (GBP) |

|---|---|---|---|---|

| Air-Dry Clay | Yes | Yes | Moderate | Low |

| Paper Clay | Yes | Yes | Moderate | Low |

| Natural Clay | Yes | Yes | High* | Moderate |

| Cold Porcelain Clay | Yes | Yes | High | Low |

| Stone Clay | Yes | Yes | High* | Moderate |

| Polymer Clay | No | No | High | High |

FAQs: Polymer Clay

Polymer clay is not considered eco-friendly as it contains toxic elements. Polyvinyl chloride (PVC) in polymer clay introduces harmful chemicals like dioxin, a known carcinogen, and phthalates, both having negative environmental impacts.

Yes, polymer clay is a type of plastic. It comprises a mixture of pigments, fillers, lubricants, plasticisers, oils, and binders. It is a synthetic oven-bake modelling material based on polyvinyl chloride (PVC), known for its flexibility and ease of use.

Polymer clay is a type of plastic that consists of pigments, fillers, lubricants, plasticisers, oils, and binders. It is a synthetic oven-bake modelling material with a polyvinyl chloride (PVC) base known for its versatility and flexibility.

Polymer clay cannot be recycled in the traditional sense. Once cured, it cannot be remoulded or returned to its original state. However, uncured scraps can be reused and incorporated into new projects, minimising waste.

Inemesit is a seasoned content writer with 9 years of experience in B2B and B2C. Her expertise in sustainability and green technologies guides readers towards eco-friendly choices, significantly contributing to the field of renewable energy and environmental sustainability.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?