- GreenMatch

- Blog

- Is Vertical Farming Bad for the Environment?

Is Vertical Farming Bad for the Environment?

- There is significant potential for vertical farming to become a sustainable and climate-resilient agricultural system worldwide.

- Vertical farming's intensive energy use remains is a considerable hurdle to its environmental sustainability.

- Vertical farming can be a viable alternative to traditional agriculture, primarily when powered by renewable energy.

As the global population is projected to surge to 9.7 billion by 2050, with a significant majority living in urban areas, the demand for food, mainly fresh fruits and vegetables, is expected to rise dramatically.

Urbanisation, which will see 68% of the world’s population living in cities by mid-century, calls for innovative approaches to food production to meet this growing demand. Among the most promising solutions is vertical farming, a form of controlled-environment agriculture (CEA) that can significantly increase crop yields while reducing land use and transportation needs.

Although vertical farming systems can be energy-intensive due to the need for artificial light and climate control, they produce fresh, high-quality produce year-round, regardless of geographic location. This is an appealing option worldwide, especially in urban or water-scarce areas.

Put simply, vertical farming can offer a sustainable approach to feeding the world's growing urban populations, ensuring that even those far from traditional farmlands have access to fresh produce.

- What Do We Mean By Vertical Farming?

- Environmental Impact of Vertical Farming

- Does it Get Rid of Transport Emissions?

- How Much Money Does It Cost Us?

- What Are the Alternatives?

- Vertical Farming Statistics

- Vertical Farming in the Largest Economies

- Examples of the Impact of Vertical Farming

- Conclusions: Is Vertical Farming Sustainable?

What Do We Mean By Vertical Farming?

On vertical farms, crops grow vertically in stacked layers rather than on the land. These highly controlled indoor environments replace natural sunlight with artificial lighting. They typically use soil-growing techniques to achieve huge crop yields compared to traditional, open-field farming, which can be limited by seasonality or unfavourable weather conditions.

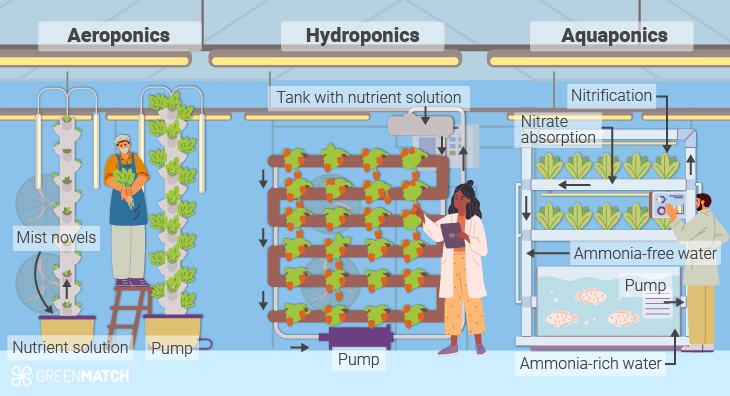

Vertical farming applications vary. Typical vertical farming growing systems include:

- Hydroponics: Crops are grown in a water-based mineral nutrient solution. These nutrients might come from animal manure or artificial water-soluble fertiliser. Various foods, such as peppers, lettuce, tomatoes, and herbs, can be grown using hydroponic farming.

- Aquaponics: This process combines aquaculture, the raising of fish, snails, or crustaceans in tanks, with hydroponic farming, described above. The nutrient-rich tank water is used to grow hydroponic plants, while the species grown in tanks can also be grown for food.

- Aeroponics: The plant roots are suspended in the air and misted with a nutrient-rich solution. Typical crops include various green vegetables, Asian greens, and fruits such as strawberries and melons.

Across the industry many types of buildings have been converted into an effective vertical farm; including shipping containers, skyscrapers, or underground mine shafts.

Environmental Impact of Vertical Farming

Vertical farming offers great potential to reduce the impact of agriculture on the planet. Some of its key characteristics help in addressing several global challenges like rapid urbanisation, food insecurity, and climate change:

- Reduced land use: Vertical farms optimise land use by using vertical space and producing higher yields, with more productivity and land use efficiency per area unit. This frees up agricultural land, which can be used to restore local biodiversity. This should also reduce deforestation and soil erosion, which are currently causing extreme environmental harm.

- Increased crop yields: As the world continues to urbanise and populations grow, so do concerns for the future of our already strained global food production system. Vertical farming emerges as a promising solution since it can produce 10 to 20 times the yield, depending on the crop, according to the US Department of Agriculture. It's also unaffected by seasonality and is highly controlled.

- Reduced water use: Vertical farming uses water recirculation techniques through closed-loop, highly precise irrigation systems. This optimises water use and minimises water waste, ensuring that crops are watered precisely as needed and that excess is recirculated. According to researchers at the Journal of Advances in Biology & Biotechnology, vertical farming uses 95% less water than open-field farming.

- Improved food quality: Vertical farming improves our public health, especially in urban areas, where access to fresh foods can be limited. Implementing vertical farming in urban areas ensures local, fresh, nutritious food cans are supplied year-round to communities in urban areas.

- Reduced chemical and pesticide use: Vertical farming reduces the environmental impact of chemicals and pesticides on our land, air, and waterways by operating within enclosed, protected environments that reduce the need for herbicides and pesticides.

In terms of energy efficiency, vertical farming can save significant energy by reducing food miles, but emissions can be made up in other ways. This push-and-pull effect has led to some debate about the environmental benefits of vertical farming.

In the following sections, we'll explore some downsides and common misconceptions about vertical farming.

Environmental Challenges of Vertical Farming

Enclosed farming techniques must rely on energy-intensive artificial lighting (usually LED), heating, and air conditioning, all of which sacrifice free renewable resources.

Even with LED lighting, there are limitations. According to researchers at the Journal of Cleaner Production, LED lighting efficiency is projected to reach a maximum of about 87% in the next 15-20 years. Still, it only achieves around 65% efficiency, resulting in significant energy wastage in both scenarios.

Therefore, the vast amounts of electricity required for large-scale vertical farming raises questions about its environmental benefits, potentially making traditional food production and transportation comparatively less harmful to the environment.

Does it Get Rid of Transport Emissions?

Fossil fuels used in transportation cause significant air pollution, impacting human health and driving climate change.

Vertical farming, perhaps, offers a potential solution that alleviates transport emissions in the food production industry since more local or urban-integrated vertical farms drastically reduce food miles.

Cecilia Stanghellini and David Katzin (Journal of Cleaner Production) point out, however, that while vertical farms can drastically reduce the supply chains in food production, they do not negate the emissions from the manufacturing and transportation of specialist vertical farming technology.

In fact, they report that transporting lettuce from Southern Italy to the Netherlands could result in less emissions than local vertical farm production, according to the following scenarios:

Scenario 1: Transporting Lettuce from Southern Europe

Transport Emissions

- Distance: 1800 km from Salerno, Italy, to the Netherlands.

- Emissions: 74 g CO2 eq per t-km (including cooling).

- For 1 kg of lettuce: 74 g CO2 eq per t km × 1.8 t = 133.2 g CO2 eq

-

Additional emissions for production: 5 g CO2 eq per kg.

- Total Emissions: 133.2 g CO2 eq + 5 g CO2 eq = 138.2 g CO2 eq per kg

Scenario 2: Local Production in Vertical Farms

Energy Consumption

- Energy required: 4.4 kWh per kg of lettuce.

-

To be competitive, the carbon footprint of electricity must be less than 32 g CO2 per kWh.

- Total Emissions: 4.4 kWh × 32 g CO2 eq per kWh = 140.8 g CO2 eq per kg

| Aspect | Transport from Southern Europe | Local Production in VFs |

|---|---|---|

| Distance | 1800 km | N/A |

| Transport Emissions | 133.2 g CO2 eq per kg | N/A |

| Production Emissions | 5 g CO2 eq per kg | 140.8 g CO2 eq per kg |

| Total Emissions | 138.2 g CO2 eq per kg | 140.8 g CO2 eq per kg |

This comparison assumes that the vertical farm does not have additional emissions related to transportation out of the vertical farm.

In terms of greenhouse gas emissions, it is slightly more preferable to transport lettuce from Southern Europe (138.2 g CO2 eq per kg) than to produce it locally in vertical farms using electricity with a carbon footprint of 32 g CO2 per kWh (140.8 g CO2 eq per kg).

However, this conclusion highly depends on the carbon footprint of the electricity used in the vertical farms. If the electricity used in vertical farms comes from renewable sources with a lower carbon footprint, local production could become more favourable, as we'll explore later in the article.

How Much Money Does It Cost Us?

From production to energy systems, high upfront expenses have become a significant barrier to the more widespread adoption of vertical farming.

According to industry estimates, constructing a single large-scale vertical farming facility could exceed around £78 million ($100 million).

Investment Costs

Real estate: Proximity to urban centres increases initial investment costs.

Construction: A large-scale vertical farming facility can cost over $100 million.

Technology: High costs for LED lights, robotics, AI, computer systems, and cameras.

Growing methods: Expensive methods like hydroponics and aeroponics.

Operating Costs

Energy: Heavy reliance on electricity for lighting and natural gas for climate control. Energy comprises about 50-70% of the cost of goods sold for vertical farms.

Control systems: Investment in systems to optimise temperature, light, humidity, oxygen, and CO2 levels.

Source: CoBank

The energy costs associated with growing plants in vertical farms make up the largest share of total operational costs, estimated at 50-70%. That's because artificial light sources, humidity control, heating, ventilation, and air conditioning are energy-intensive and must be operated year-round to ensure optimal output.

What's more, high upfront costs and energy needs result in long payback periods, taking around 5 times as long to break even compared to open-field farming.

Source: CoBank

The high proportion of electricity costs underscores the importance of energy efficiency and the potential benefits of integrating renewable energy sources.

However, renewable energy comes with resource demands and environmental costs. Roughly 3-4 acres of solar panels are needed to produce one megawatt/month of electricity. For comparison, a vertical farm producing 25,000 pounds of produce per month would need about 1.5 acres of solar panels to source all of its power needs.

What Are the Alternatives?

As an agricultural system, greenhouses offer natural and technological solutions to enhance crop production. Therefore, it is an alternative between open field's minimal control and vertical farming's highly controlled environment.

Unlike vertical farming, which relies heavily on artificial lighting and climate control, greenhouses use the sun's natural energy to heat the enclosed space while mitigating temperature extremes through natural ventilation.

Modern greenhouse farming is not limited to passive systems. 'High-tech' greenhouses use advanced technology to automate and fine-tune various environmental factors. For example, automated ventilation systems can precisely regulate the internal temperature, ensuring optimal growing conditions regardless of external weather.

In addition, systems for heating or cooling can be employed to maintain a consistent climate, further reducing the impact of seasonal fluctuations. Carbon dioxide enrichment can boost plant growth, and supplementary lighting can extend growing seasons or enhance crop yields during low-light conditions.

While greenhouses do not offer the same level of control as vertical farming, they can provide a more sustainable and often more cost-effective solution for increasing productivity than open-field cultivation.

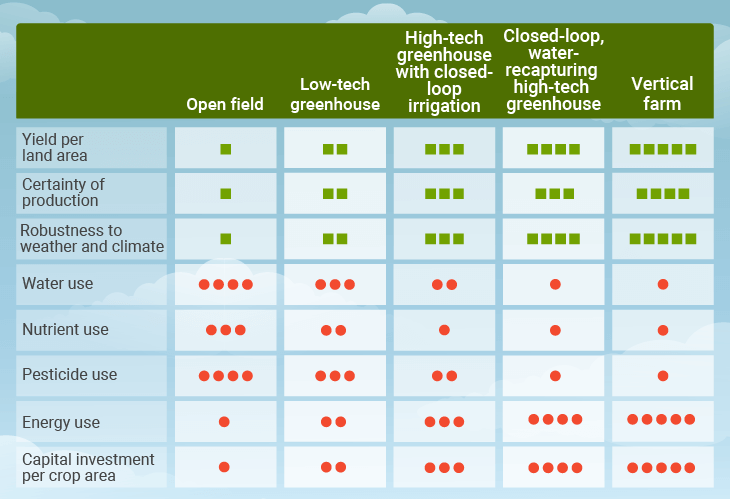

Is It Better Than Alternatives?

Both vertical farms and high-tech greenhouses use closed-loop systems which minimise chemical emissions and fertilisers being released into the environment. Both systems can significantly reduce water and nutrient use compared to open-field techniques while maintaining high productivity levels.

The performance of various protected cultivation systems can be assessed based on several parameters. Generally, as the technological sophistication of these systems increases, so do the associated yields and production certainty. However, this also leads to higher capital investment and energy consumption.

With this in mind, the table below summarises the performance capabilities of various types of agricultural systems.

Source: Journal for Cleaner Production

Vertical farms and high-tech greenhouses both offer advanced resource efficiency and production reliability. However, vertical farms often require a higher initial investment and greater energy consumption due to their reliance on artificial lighting and climate control systems. The trade-off is that they offer unmatched control over growing conditions, leading to higher yields and less land use.

Yet, the environmental and financial impact of the substantial electricity demands in vertical farming raises concerns about its long-term sustainability. In contrast, while slightly less productive, high-tech greenhouses rely on natural sunlight and achieve significant resource savings with lower energy costs.

Vertical Farming Statistics

By 2050, a 50-100% increase in food production per hectare on existing land will be required to meet global demand.

As of 2018, 55% of the world's population resides in urban areas, with rural populations projected to decline by 11% by 2030.

Currently, agriculture accounts for 70% of global water consumption. Thanks to closed-loop water systems, vertical farming consumes 95% less water than conventional farming.

Vertical farming can achieve 10 to 20 times the yield per acre compared to traditional open-field agriculture.

Indoor vertical farming can be 100 times more productive in leafy lettuce cultivation than conventional methods and 15 times more productive than high-tech greenhouses.

The global vertical farming market was valued at $5.6 billion in 2022 (£4 billion) and is expected to surpass $35 billion by 2032 (£27 billion).

Vertical Farming in the Largest Economies

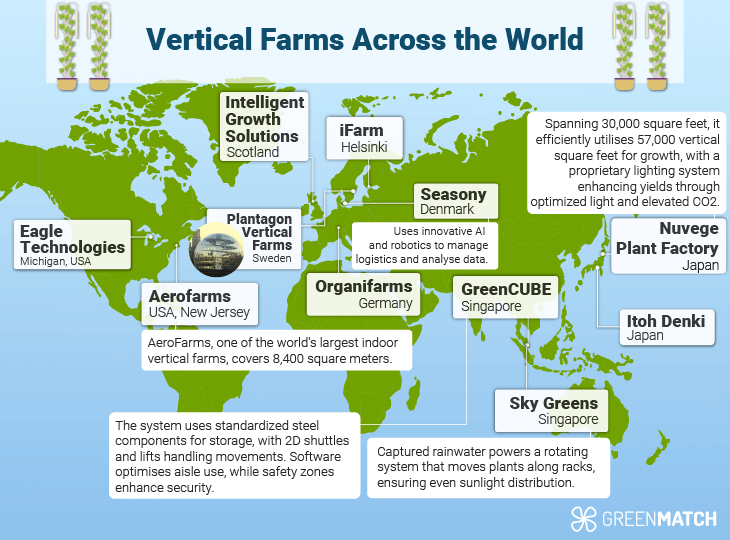

Vertical farming has emerged as a global solution to enhance resource use efficiency, particularly in terms of energy, water, and nutrients, to address the challenges of urbanisation and food security.

Vertical farming has been widely employed in East and Southeast Asian countries, North America and Europe.

In 2009, the world's first pilot production system was installed at Paignton Zoo Environmental Park in the United Kingdom. The project showcased vertical farming and provided a physical base to research sustainable urban food production.

In 2012, the world's first commercial vertical farm was opened in Singapore. Sky Greens Frms developed it, and it is three stories high.

Located in New Jersey, AeroFarms is one of the largest indoor vertical farms, taking up 8,400 square meters of space with an aeroponic growing system.

Examples of the Impact of Vertical Farming

To evaluate its environmental impacts, we can look at two case studies: one from Sweden and another from Scotland. These case studies underscore the enormous potential of vertical farming when coupled with renewable energy sources.

In Sweden, vertical farming systems reveal that electricity consumption is the primary driver of environmental impacts. In terms of water and land use, electricity’s impact is even greater due to Sweden’s significant reliance on hydropower and nuclear energy in its electricity mix.

For example, the baseline scenario of vertical farming lettuce shows greenhouse gas (GHG) emissions of approximately 0.98 kg CO2-eq per kg of lettuce.

However, incorporating renewable energy sources significantly reduces these emissions. Scenarios using wind or hydro/wind power lower GHG emissions to about 0.77 and 0.75 kg CO2-eq per kg, respectively.

Compared to conventional lettuce production, vertical farming often demonstrates lower GHG emissions, especially when energy sources are optimised.

The environmental impact of transporting and processing imported lettuce often results in higher overall emissions, making vertical farming a competitive option for reducing carbon footprints.

Source: Journal of Sustainable Production and Consumption (2023)

In Scotland, life cycle analyses of vertical farming with lettuce highlight that electricity consumption constitutes 91% of the carbon footprint.

In 2019, the carbon emissions for Scottish vertical farming lettuce were approximately 1.49 kg CO2-eq per kg, placing it less favourably compared to UK open-field lettuce and Spanish imports.

However, as Scotland’s electricity mix increasingly incorporates renewable energy, the emissions from vertical farming dropped significantly. By 2020, emissions had reduced to 0.42 kg CO2-eq per kg, aligning closely with UK open-field agriculture’s emissions of about 0.46 kg CO2-eq per kg.

With a hypothetical shift to 100% renewable electricity, vertical farming emissions could further decrease to 0.33 kg CO2-eq per kg, highlighting a substantial potential for low-carbon production.

Source: Journal of Food and Energy Security (2023)

In summary:

The Swedish study highlights that while vertical farming can produce lower greenhouse gas (GHG) emissions than imported lettuce, it still faces resource use and water consumption challenges.

Similarly, the Scottish case study underscores vertical farming's potential as a low-carbon production method, with significant reductions in GHG emissions achievable through integrating renewable energy.

Conclusions: Is Vertical Farming Sustainable?

Despite the advantages, vertical farming's intensive energy use remains a significant hurdle to its environmental sustainability. Proponents of vertical farming argue that this can be mitigated or that the benefits—such as water savings and reduced pesticide use—outweigh the drawbacks.

The sustainability potential of vertical farming is evident in both the Swedish and Scottish case studies, demonstrating that vertical farming can be a viable alternative to traditional agriculture, primarily when powered by renewable energy.

While the enthusiasm for vertical farming is tempered by the current struggles faced by many vertical farming businesses, the potential for vertical farming to become a sustainable and climate-resilient agricultural system remains significant, particularly as renewable energy technologies continue to advance.

Ciaran is a content writer at GreenMatch. Whether writing about sustainable aviation fuel or heat pumps, Ciaran has passion for informing readers about pivotal technologies that are reshaping our world.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?

- What Do We Mean By Vertical Farming?

- Environmental Impact of Vertical Farming

- Does it Get Rid of Transport Emissions?

- How Much Money Does It Cost Us?

- What Are the Alternatives?

- Vertical Farming Statistics

- Vertical Farming in the Largest Economies

- Examples of the Impact of Vertical Farming

- Conclusions: Is Vertical Farming Sustainable?