- GreenMatch

- Blog

- Sustainable Packaging

Is Sustainable Packaging Bad For The Environment? Statistics, Trends & Facts

- Sustainable packaging options are in high demand as 76% of consumers in the UK, Europe, and the United States prefer paper-based packaging over plastic for environmental reasons.

- Over 50% of all plastic waste comes from short-use plastics, with 40% from packaging alone.

- In 2019, the plastics industry released 1.8 billion metric tonnes of greenhouse gas emissions, accounting for 3.4% of global emissions.

- The global sustainable packaging market is on the rise. It was valued at around £214.77 billion in 2023 and projected to reach £387.68 billion by 2032.

"Reduce, reuse, recycle" are the actual three words of love our planet Earth wants to hear. And we think we're contributing to this mission as we drop that paper coffee cup in the recycling bin. Yet the cold, hard fact is that only 1 in 400 paper cups are recycled in the UK each year!

Therefore, this raises the question: "Is sustainable packaging truly effective in reducing waste?" Or is sustainable packaging bad for the environment at the end of the day? There's only one way to know, and it's a deep research. Let's dive in.

- What do we mean by sustainable packaging exactly?

- What kinds of sustainable packaging materials are there?

- Environmental impact of sustainable packaging

- How can you measure the environmental impact of packaging?

- Is sustainable packaging toxic?

- Can you recycle sustainable packaging?

- Is sustainable packaging biodegradable?

- Can you get rid of sustainable packaging?

- What can you do with leftover sustainable packaging?

- Environmental impact compared to everyday things

- Statistics, facts and figures about sustainable packaging

- What are sustainable packaging alternatives?

- Future trends and innovations

- FAQ

What do we mean by sustainable packaging exactly?

Sustainable packaging uses materials and methods which minimise environmental impact throughout the product's lifecycle. The 3 key aspects of sustainable packaging include:

- Material choice: Employing paper, cardboard, glass, plant-based plastics, compostable, and already recycled materials in packaging reduces the need for new resources.

- Design and production: Sourcing the materials locally and, in general, reducing the amount of material used through efficient design. This also means using manufacturing processes that consume less energy and produce fewer emissions.

- End-of-life use: Designing packaging that can be easily recycled or upcycled in existing systems. For unrecyclable items, this means designing packaging that breaks down naturally without harmful residues.

While these three aspects theoretically allow many packaging materials to meet the sustainability criteria, the reality may not be as clear. In fact, many corporations use recyclability and sustainability of packaging as marketing tactics, often without delivering on their promises.

For example, food industry behemoths Coca-Cola, Danone, and Nestle have been accused of making misleading claims about their plastic bottles being “100% recycled” or “100% recyclable” while never actually making bottles wholly of recycled materials. Other companies choose to use vague and undefined claims like “95% naturally derived” or “ethically sourced,” which lacks transparency.

Some companies also state that their products are sustainable because they either contain or are made of recycled plastics, forgetting to mention that those plastics are as toxic for the environment as their "eco-unfriendly" alternatives.

All that can hardly be called sustainable, of course. But what can, you may ask?

True sustainability generally refers to practices and systems that can be maintained indefinitely without depleting resources or causing environmental harm. This concept typically encompasses the environmental, economic, social, and technological aspects.

From this perspective, sustainable packaging should be designed for durability and reusability. This will eliminate or drastically reduce the need for frequent replacements and minimise waste. This process is called upcycling.

Therefore, using renewable (wood), infinitely recyclable (aluminium and steel), and natural, biodegradable materials like banana leaves as packaging materials can offer unique and true sustainability benefits.

What kinds of sustainable packaging materials are there?

There are a number of sustainable packaging material types available. Choosing a certain material often depends on the specific product requirements, local recycling infrastructure, and overall goals of the company.

| Material | Made from | Used for |

|---|---|---|

| Paper/Cardboard | Wood pulp, recycled paper | Food packaging, shipping boxes, cups |

| Corrugated cardboard | Old corrugated containers | Product packaging, shipping boxes |

| Bioplastics | Cornstarch, sugarcane, algae | Food containers, cutlery, flexible packaging |

| Aluminum | Bauxite ore, recycled aluminium | Beverage cans, food packaging |

| Glass | Sand, recycled glass | Bottles, jars |

| Biodegradable air peanuts | Starch-based materials | Cushioning for shipping |

| Cornstarch packaging | Corn | Food packaging, packing peanuts |

| Seaweed packaging | Seaweed, algae | Single-use food packaging |

| Organic textiles | Hemp, cotton, palm leaves | Bags, cushioning, bundling |

| Cellulose-based packaging | Hemp, wood, cotton | Food packaging, pharmaceutical packaging |

| Paper cups (PE-coated)* | Wood pulp, polyethylene coating | Hot and cold beverages |

There are also innovative packaging materials emerging to the industry, such as milk protein (casein), coconut husks, and limestone-based materials. Casein-based films are proven to be 500 times better than plastics or starch at barriering food from oxygen. They are also biodegradable, sustainable, and edible.

Coconut husks are high in lignin, a natural enduring and sturdy polymer which can be considered a plastics alternative. Derived from coconut shells, it can assist in reducing waste from coconut processing as they can be used as disposable or resusable bowls.

Limestone-based materials are a base for LIMEX, which is a recyclable alternative to plastic. Made with 60% of limestone and 40% of polyolefin, LIMEX reduces the reliance on petroleum-based plastics by up to 33%.

Environmental impact of sustainable packaging

The environmental impact of sustainable packaging stretches beyond its production and disposal. While there are certainly environmental benefits, some challenges and trade-offs are coming along.

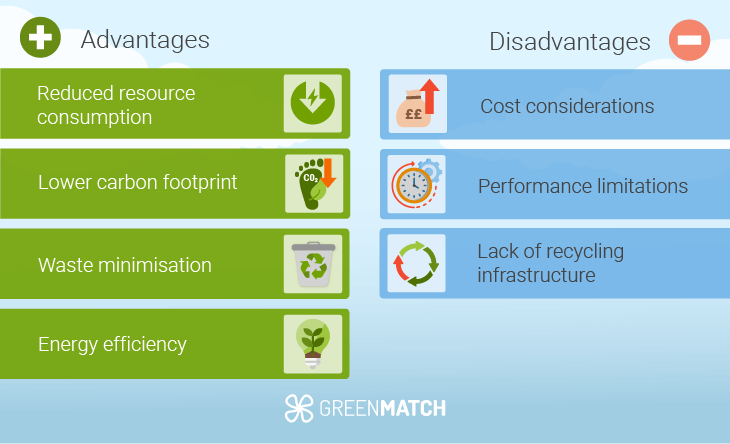

Environmental benefits

Manufacturing sustainable packaging typically uses renewable resources such as plant-based materials. These are bioplastics (starch, cellulose, PLA), bamboo, bagasse, hemp, and mycelium (the root structure of mushrooms). This results in several core advantages:

- Reduced resource consumption: Utilisation of renewable resources lessens reliance on the limited supply of petroleum oil. According to the US Energy Information Administration, the petrochemical sector uses roughly 4% of the nation's annual energy production.

- Lower carbon footprint: Because sustainable packaging produces and transports with fewer greenhouse gas emissions, it helps to mitigate climate change. For instance, producing PLA produces roughly 60% fewer greenhouse emissions than producing traditional plastics. Furthermore, creating environmentally friendly, lightweight packaging lowers the energy needed for transportation, which in 2023 was responsible for nearly 28% of all greenhouse gas emissions in the US.

- Waste minimisation: Designs utilising fewer materials or designs that are recyclable and biodegradable reduce the volume of waste sent to landfills and oceans. For instance, paper-based packaging has a recycling rate of 68% in the US, compared to plastic packaging, which has a recycling rate of only 9%.

- Energy efficiency: Producing recycled paper takes up to 68% less energy than producing virgin paper. In a similar fashion, bioplastics typically require less energy to produce their own petroleum-based counterparts.

Challenges

- Cost considerations: Recycled paper and biodegradable plastics are more expensive than their conventional counterparts. New machinery or technologies might be needed for production, which could increase the cost of manufacturing. Governmental incentives, however, can defray the initial expenses.

- Performance limitations: Certain environmentally friendly materials and reusable packaging cannot endure repeated uses or offer the required degree of protection against moisture and oxygen.

- Lack of recycling infrastructure: Variations in recycling capacities among various regions can make material selections and packaging design more challenging to implement. Certain environmentally friendly materials might need unique recycling techniques that are not commonly accessible.

How can you measure the environmental impact of packaging?

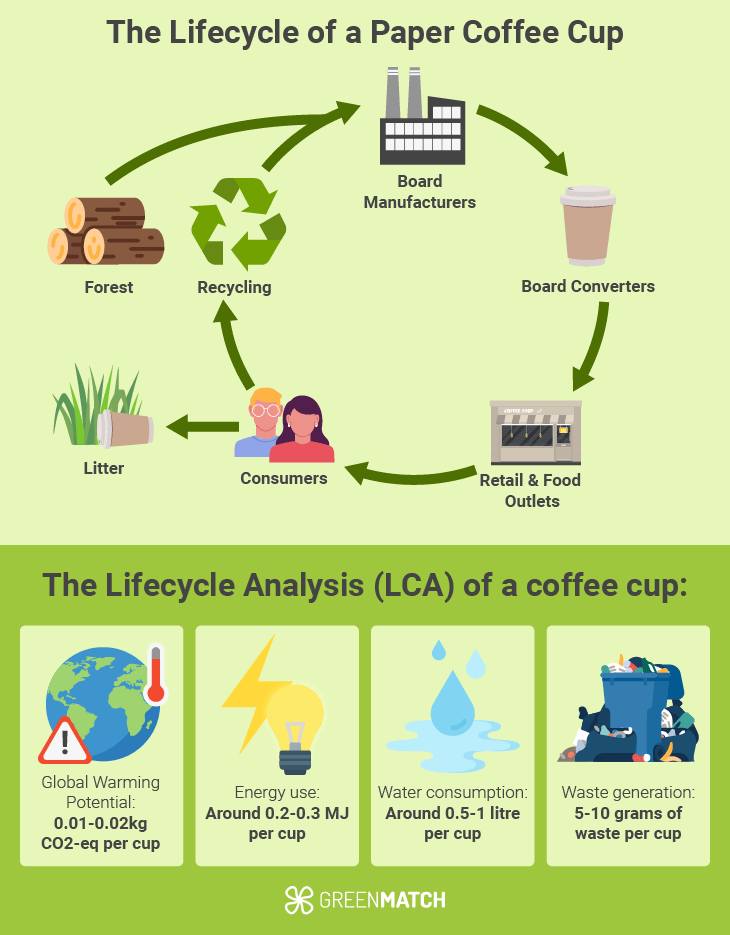

There's a process called lifecycle analysis (LCA) that assesses the environmental impact of packaging, from raw materials to end-of-life disposal. LCA usually involves 5 main phases:

- Material sourcing: Selecting recycled or renewable materials helps the environment.

- Manufacturing: Less waste production and energy-efficient procedures are given priority.

- Distribution: Compact and lightweight designs reduce emissions from transportation.

- Usage: Packaging that is easily recyclable or reusable prolongs the life of the substance.

- End-of-life: Materials that are recyclable or compostable allow packaging to be disposed of or reused in an environmentally responsible manner.

Key LCA metrics include:

- Global Warming Potential (GWP): Measures the carbon footprint of packaging throughout its lifecycle and is expressed in CO2 equivalents.

- Energy use: Assesses the total energy consumed during production (both renewable and non-renewable), transportation, and disposal. It can be expressed in megajoules (MJ) or kilowatt-hours (kWh).

- Water consumption: Evaluate the water usage across all stages of the packaging lifecycle. Includes both direct water use in production and indirect use in raw material production.

- Waste generation: Measures the amount of waste produced during manufacturing and at end-of-life, including solid and liquid waste and emissions.

Let's take a paper cup's lifecycle to better understand the process.

Sourcing raw materials

Trees are taken down from forests, and wood is turned into pulp in paper mills. By using chemistry (cationic starch, PAM derivatives, or synthetic strength resins and such) to increase fibre strength, less raw material can be required.

Producing

Paperboard is made from pulp. Chemical recycling processes guarantee the materials' stiffness, strength, and water-repellent qualities. Boards are designed to be produced at high speeds—up to hundreds of tonnes every day.

Forming cups is done with the help of fast-converting devices (about 330 cups per minute). Chemistry allows for the essential stiffness and elasticity in low-weight boards. The exact application of pressure and heat forms cups. Cups are printed and coated to make them resistant to liquids. Designs for branding and marketing are used.

Usage

Distributed cups are given to food service businesses. A single-use application for hot or cold beverages offers thermal insulation, hygienic conditions, and safety.

End-of-life recycling

In an ideal world, these cups get recycled. They're collected, sorted, and put through a process that strips away inks and coatings. The plastic lining is filtered out, and the remaining fibres are given a new lease on life, often reincarnating as materials for non-food products.

Of course, not all cups meet this eco-friendly fate. Some might end up being burned for energy, while others – if they're of a special compostable variety – could nourish the soil in industrial composting facilities. Unfortunately, many still find their way to landfills, a less-than-ideal end to their journey.

Is sustainable packaging toxic?

As a rule, sustainable packaging is less toxic than traditional packaging. However, it's crucial to understand that not all sustainable packaging is non-toxic. The materials used, production processes, and end-of-life management all influence the toxicity of the packaging material.

Compostable and bio-based materials, in fact, might contain toxic substances that pose environmental and health risks.

- Health concerns

For example, compostable plastic packaging, often called an eco-friendly alternative to plastic, sadly contains toxic per- and poly-fluoroalkyl (PFAS), also known as "forever chemicals." While these chemicals are good at repelling water and grease in food packaging, they are also linked to serious health problems, including cancer, liver problems, thyroid issues, birth defects, kidney disease, and decreased immunity.

- Increased toxicity

A peer-reviewed study found that PFAS chemicals can migrate to food and drinks when they break off from the packaging.

Another study revealed that the degradation of compostable plastics boosts their toxicity. When exposed to the sun, compostable and biodegradable plastics showed increased toxicity compared to conventional plastics. This means that the degradation and composting of biodegradable plastics can also form harmful compounds, such as dicarboxylic acid and toxic leachates, which are released then into the environment.

As for paper and cardboard, research by the Swedish Chemicals Agency found that 80% of paper and cardboard food packaging contained toxic chemicals such as endocrine disruptors like DEHP, DBP, and BPA.

- Risk of hazards

Hazardous substances were found in bio-based food contact materials (FCMs), which are made from plant biomass, despite their eco-friendly image. These chemicals can originate from various sources, including raw materials, production processes, or even during use.

The presence of polluted soils, pesticides, and additives in the production chain can significantly increase the number and diversity of substances in the final product. Concerningly, many products marketed as "eco-friendly" or "natural" have been discovered to contain plastic coatings, pesticide residues, per- and polyfluoroalkyl substances (PFAS), and phthalates.

| Aspect | Sustainable packaging | Conventional packaging |

|---|---|---|

| Material source | Renewable resources (e.g., plants, recycled materials) | Non-renewable resources (e.g., petroleum-based plastics) |

| Chemical additives | May use fewer or different additives, some potentially toxic | Often contain phthalates, bisphenol A (BPA), and other toxic chemicals |

| End-of-life impact | Biodegradable or recyclable, generally lower toxicity | Persistent in the environment, potential for chemical leaching |

| Energy consumption | Typically lower, reducing indirect environmental toxicity | Higher energy usage, contributing to pollution and climate change |

Many legal requirements and certifications are in place to guarantee the security and non-toxicity of sustainable packaging:

- FDA Compliance: In order to guarantee that any substances that transfer from packaging to food are within safe bounds, packaging materials referred to for food contact must abide by FDA regulations.

- The Global Organic Textile Standard (GOTS) regulates the use of particular substances along with processes in packaging that are biodegradable and compostable in order to guarantee that they are not toxic.

- ISO guidelines: International standards define acceptable degradation rates and non-toxic byproducts, such as ISO 18604 for biodegradable plastics.

Can you recycle sustainable packaging?

Of course you can! However, recyclability depends on the specific materials used and the local recycling infrastructure, as not all regions have the infrastructure to recycle all types of sustainable packaging.

On top of that, multi-layer or composite materials (e.g., laminates) are often difficult to recycle due to the challenge of separating different materials. Only pure PE film can currently be recycled and reused to make new packaging film. Recycled PE cannot be used for food packaging due to regulatory restrictions.

| Material | Recyclability |

|---|---|

| Paper/Cardboard | Up to 75-85% (EU target by 2030) |

| Corrugated cardboard | Can be recycled up to 25 times |

| Bioplastics | Compostable, not widely recyclable |

| Aluminum | Infinitely recyclable, with high recycling rates |

| Glass | Infinitely recyclable, 60-75% (EU target) |

| Biodegradable air peanuts | Biodegradable, not typically recycled |

| Cornstarch packaging | Biodegradable, not typically recycled |

| Seaweed packaging | Biodegradable, not typically recycled |

| Organic textiles | Biodegradable, sometimes reusable |

| Cellulose-based packaging | Biodegradable, compostable |

| Paper cups (PE-coated) | Very low (0.25%-2.8% compared to 70.6% for paper and cardboard) |

With 73% of consumers stating they want to change their purchasing habits to reduce environmental impact, companies are forced to adopt greener practices. Educating consumers about proper disposal and recycling methods is essential to maximise the environmental benefits of sustainable packaging.

Additionally, transparency in labelling helps consumers make informed choices, fostering a culture of sustainability.

Recycling infrastructure of various countries

It's also important to note that recyclability rates vary greatly depending on local recycling infrastructure and consumer behaviour.

For example, Germany, Austria and Slovenia take the lead among the EU countries in recycling. The economic strength and bigger investment in recycling over the past 35 years are the core reasons why Germany and Austria have high recycling rates.

Slovenia, despite being not as economically strong as the 2 abovementioned countries and joining the EU as late as 2004, achieved impressive recycling rates due to the early adoption of waste management strategies and technological innovation. Ljubljana, the capital, became Europe's first capital to declare becoming a Zero Waste city in 2014.

Slovenia's waste management educational incentives started in the early 2000s, most probably as part of Slovenia's efforts to join the European Union. In 2002, Ljubljana started setting up roadside bins for separate paper, glass, and packaging collections. This marked the beginning of serious efforts to tackle waste management issues. In 2006, local authorities began collecting biodegradable waste door-to-door.

However, countries like Kosovo, Montenegro, and Romania hold the lowest recycling rates. They have limited infrastructure for collecting, sorting, and processing recyclable materials. Kosovo, in particular, doesn't comply with EU standards by allowing waste disposal in landfills that lack adequate liners, methane capture systems, and recycling facilities.

In addition, 99% of Kosovo's waste is sent to landfills, and there's no "pay as you throw" system; households pay a fixed monthly fee for waste collection and disposal.

Therefore, while sustainable materials might be widely used and appraised, their eco-friendliness depends on the effectiveness of each country's waste management system.

Is sustainable packaging biodegradable?

It's important to understand that sustainable packaging can be biodegradable, but not all sustainable packaging is biodegradable. Therefore, sustainability and biodegradability are not interchangeable.

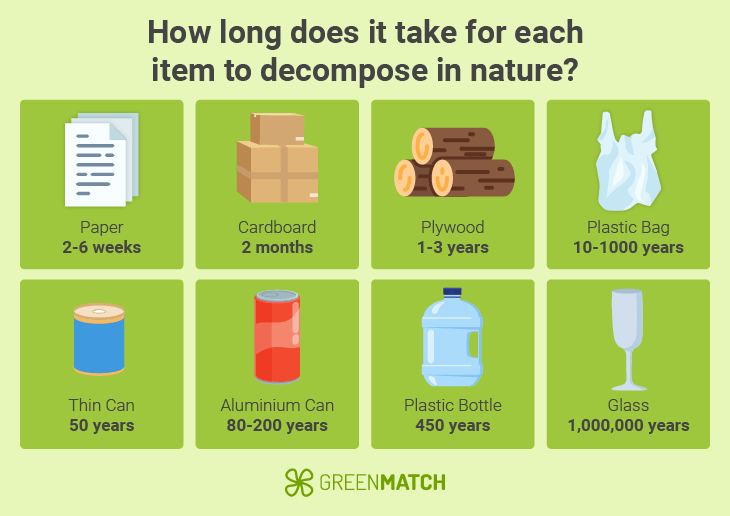

Microorganisms can break down biodegradable packaging made of cornstarch, mushrooms, seaweed, and paper into water, CO2, and biomass, usually within a year.

| Material type | Decomposition time | Conditions |

|---|---|---|

| Compostable bags | 3-6 months | Composting environment* |

| Cellulose-based packaging | 1-5 months | Varies with environmental factors |

| PLA (polylactic acid) | 3-6 months | Commercial composting facilities |

| Starch-based biodegradable packaging | 3-6 months | Ideal composting conditions |

| Biodegradable plastics | 3-6 months to several years | Optimal conditions |

| Paper | 2-6 weeks | Moist soil |

| Cardboard | 2 months | Moist soil |

| Bamboo | 4-6 months | Composting environment |

| Seaweed-based packaging | 4-6 months | Marine environment |

| Cork | 1-3 years | Natural environment |

There's also compostable packaging, which can break down into non-toxic components but needs specific conditions to break down properly.

It’s worth remembering that although materials like aluminium or PET (polyethene terephthalate) are considered sustainable, they are not biodegradable. Also, while bio-based plastics are made from renewable materials, they can’t be automatically considered biodegradable. However, some bio-based plastics, like PLA (polylactic acid), can last for 10-20 years indoors, but they can be biodegradable under certain composting conditions.

On top of that, some sustainable packaging isn't designed to be biodegradable but rather recycled.

Can you get rid of sustainable packaging?

Eco-friendly packaging is made to be as low-impact as possible during its entire life, including when it comes to disposal. Nonetheless, there are appropriate methods for managing and getting rid of various kinds of eco-friendly packaging materials:

Recycling: A lot of eco-friendly packaging materials can be recycled. For detailed details, see your community's recycling regulations. Packaging made of paper and cardboard can frequently be recycled using regular recycling processes. Certain polymers, such as PET and HDPE, are widely recyclable.

Composting: A variety of environmentally friendly packaging materials, particularly those derived from plants, can be broken down into compost. Verify whether the packaging is approved for composting and adhere to any regional composting regulations.

Reuse: A few eco-friendly packaging options are made to be used more than once. Before throwing out containers or bags, think about another use for them.

Burning packaging is generally not advised because of the possibility of harmful emissions and fire risks. While certain biodegradable packaging might be appropriate for high-temperature commercial composting facilities, this is different from burning it at home.

What can you do with leftover sustainable packaging?

Making crafts or storing them out of old containers is a great repurposing option to allow the packaging to serve longer.

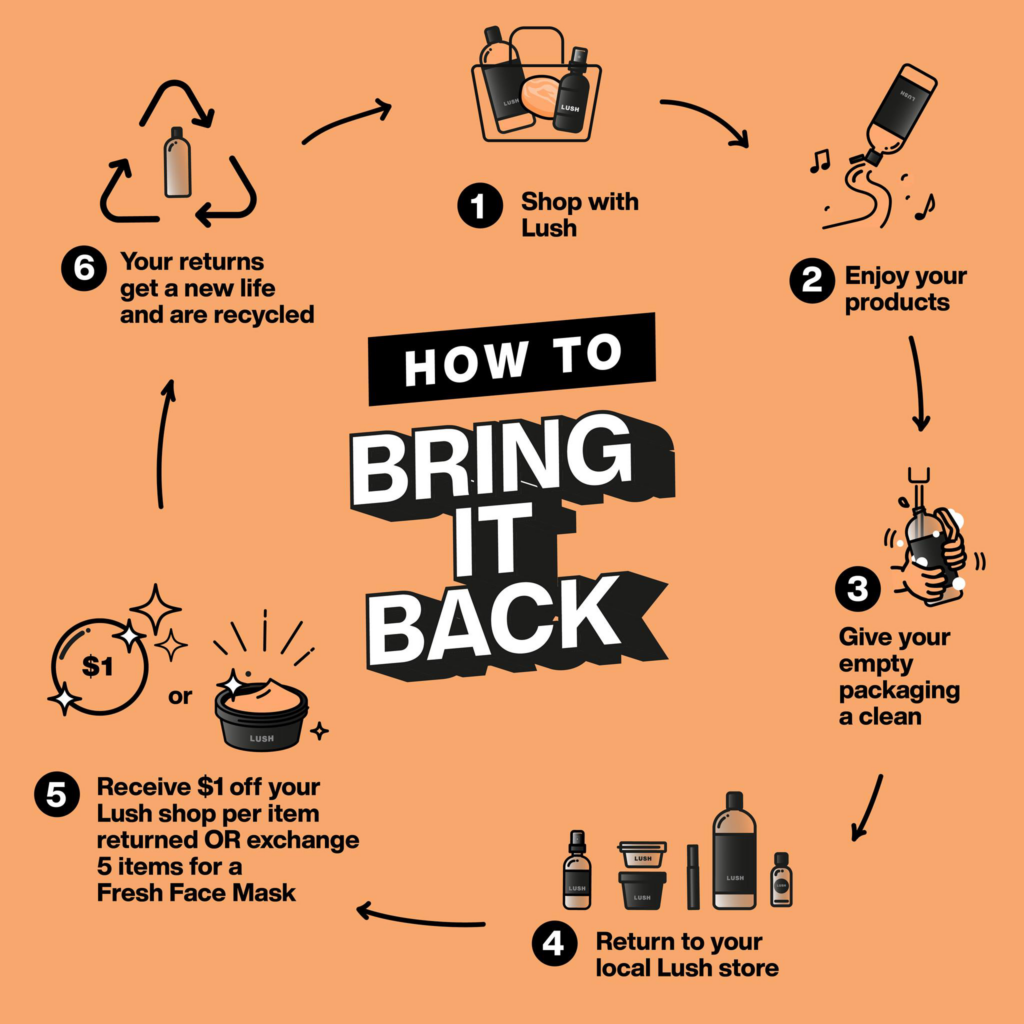

Returning packaging is an emerging policy companies are adopting to show responsibility for their products' end-of-life use. For example, Lush, a skincare brand, offers incentives for returning empty plastic pots in exchange for free products in its Bring It Back recycling program.

Elevate Packaging provides a biodegradable packaging take-back program. Used compostables can be returned by customers, and a network of partner composters will process them after that. The goal of this initiative is to decrease landfill waste and boost involvement in composting.

Environmental impact compared to everyday things

Impact of plastic bottles

Over the course of a year, if consumers opted to drink soda in PET plastic bottles rather than glass ones, it would be comparable to:

- When recycling instead of disposing of waste in landfills, around 53,000 garbage trucks' worth of greenhouse gas emissions are averted.

- The carbon stored in the over 1.3 million more acres of US forest

Aluminium can impact

Over the course of a year, if people in the UK decide to drink soda in PET plastic bottles rather than aluminium cans, it would be the same as:

- 688,000 gas-powered vehicles are taken off the road per year

- 4.4 billion litres of water were saved.

- 138 million garbage-filled bags were diverted from landfills to be recycled

Aluminium vs. plastic water bottles

A 355 ml aluminium can of normal capacity in comparison to a 500 ml PET plastic water bottle:

- 80% less solid trash is produced

- uses 53% less water during production

- has a 74% lower potential for global warming

- produces 68–83% fewer pollutants that are linked to the development of smog and acid rain.

Impact of glass bottles

Compared to aluminium cans, glass bottles contribute to global warming by approximately 95%.

Emissions from the production of plastic:

- 1.8 billion metric tonnes of greenhouse gas emissions from the plastics industry were released in 2019, making up 3.4% of all emissions worldwide.

- 95% less energy is required to produce a new can when an aluminium can is recycled.

Statistics, facts and figures about sustainable packaging

- 76% of consumers in the UK, Europe, and the United States prefer paper-based packaging over plastic for environmental reasons.

- 33% of consumers rank glass as the safest packaging material, compared to 22-26% for plastic, metal, and paper.

- The Asia Pacific region is leading in the development of sustainable packaging solutions.

- The global sustainable packaging market was valued at approximately £214.77 billion in 2023.

- The market is expected to exceed £310.47 billion by 2028.

- By 2032, the sustainable packaging market is projected to reach £387.68 billion.

- Over 50% of all plastic waste comes from short-use plastics, with 40% from packaging alone.

- Microsoft used LCA to transition from polyethene bags to glassine paper in their hardware packaging, resulting in an 85% reduction in fossil fuel use and a 69% decrease in water consumption.

- A study comparing PET bottles to refillable glass bottles found that despite the perception of glass as more eco-friendly, PET bottles had a lower environmental impact when considering the entire lifecycle, particularly due to transportation efficiency.

- A standard paper cup has a carbon footprint of 8.1g CO2-eq, which can be reduced to 3.8g CO2-eq when 100% recycled.

What are sustainable packaging alternatives?

Sustainable packaging is good, but can it get even better? Any sustainable alternative shouldn't compromise the full lifecycle impact of a material, including production, transportation, use and end-of-life disposal. Here are some options to consider:

- Paper-based packaging: Unbleached kraft paper or moulded pulp packaging is biodegradable, while glassline paper is grease-resistant and compostable.

- Plant-based materials: Biodegradable plastics (PLA) can be compostable in industrial facilities, mushroom packaging is fully biodegradable and seaweed-based options are water-soluble and edible in some cases.

- Reusable options: Glass jars and bottles can be recyclable and reusable, while silicon bags and containers are a durable alternative to single-use plastics

- Natural materials: Palm leaf packaging is biodegradable, while bamboo is also renewable; wool packaging is a biodegradable insulation option for shipping perishables.

It's worth noticing that reduced packaging usage is one of the best ways to improve sustainability and promote a circular economy.

However, while seeking more sustainable packaging alternatives requires a good deal of research and critical thinking, reducing packaging consumption is mainly about changing our consumer behaviour and patterns. Therefore, simply using less and being mindful of our choices can significantly reduce waste and conserve resources.

Future trends and innovations

- Smart packaging: Integration of technology to monitor product freshness and reduce waste. For example, time-temperature indicators (TTIs) can change colour or display messages when products are exposed to unfavourable conditions. RFID tags and QR codes enable traceability across the supply chain and provide consumers with detailed product information.

- Edible packaging: Developing edible films made from seaweed or plant-based materials, as well as dissolvable packaging for single-use items like laundry pods, edible cutlery, and straws made from rice or wheat bran. Companies like Notpla, Evoware, and Loliware utilise seaweed as an alternative to plastic packaging.

- Circular economy models: Encouraging the reuse and regeneration of packaging materials to create a closed-loop system. For example, industrial symbiosis involves companies exchanging surplus materials and creating green business models, as seen in Denmark, where 25 companies exchanged residual products like water, energy, and materials. The Danish deposit and return system for recycling drink cans and bottles is another prime example of increasing recycling rates and supporting the circular economy.

In the packaging industry, companies like Plus Pack and Circqle are developing reuse packaging-as-a-service models, focusing on closed-loop systems for food packaging. These circular models can reduce CO2 emissions by up to 60% compared to single-use packaging. Other approaches include designing products for longevity and repairability, implementing take-back programs, and using recycled materials in manufacturing processes. - Advanced recycling techniques: Chemical recycling breaks down plastics into their base components, enabling the recycling of previously non-recyclable materials. Pyrolysis (breaking down plastic into liquid hydrocarbon products), solvolysis (PET depolymerisation), thermochemical depolymerisation (converting plastic waste into chemical-rich gas and monomers) and dissolution (dissolving of target polymers) are the core technologies to become part of the advanced recycling loop.

Specialised facilities are being developed to process complex materials like bioplastics, while AI and machine learning enhance sorting accuracy and efficiency.

Other packaging innovations complement these recycling advancements. Active packaging, incorporating oxygen scavengers and moisture absorbers, extends product shelf life, while antimicrobial properties eradicate bacteria. Portion control packaging reduces over-consumption and food waste by dispensing specific amounts. Additionally, developing biodegradable and compostable options expands the range of sustainable materials available.

FAQ

Recycled paper, cardboard, bioplastics, reusable and compostable materials are considered sustainable packaging options.

Look for certifications like FSC (Forest Stewardship Council) for paper products, recycling symbols, or claims about biodegradability or compostability. Also, consider the material’s recyclability and the overall lifecycle impact.

Yes, many sustainable packaging solutions can be just as effective as traditional packaging in terms of product protection, shelf life, and functionality.

Some of the most eco-friendly packaging materials include recycled paper and cardboard, glass, aluminium, and certain bioplastics. The best choice often depends on the specific application and local recycling infrastructure.

Paper packaging is often considered more sustainable because it’s biodegradable and easier to recycle. However, the answer can vary depending on factors like production methods, transportation, and end-of-life disposal.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?

- What do we mean by sustainable packaging exactly?

- What kinds of sustainable packaging materials are there?

- Environmental impact of sustainable packaging

- How can you measure the environmental impact of packaging?

- Is sustainable packaging toxic?

- Can you recycle sustainable packaging?

- Is sustainable packaging biodegradable?

- Can you get rid of sustainable packaging?

- What can you do with leftover sustainable packaging?

- Environmental impact compared to everyday things

- Statistics, facts and figures about sustainable packaging

- What are sustainable packaging alternatives?

- Future trends and innovations

- FAQ