- GreenMatch

- Blog

- Are Bricks Bad for the Environment? Stats, Trends and Facts

Are Bricks Bad for the Environment?

In our quest to build durable, enduring structures, bricks have been a cornerstone for generations.

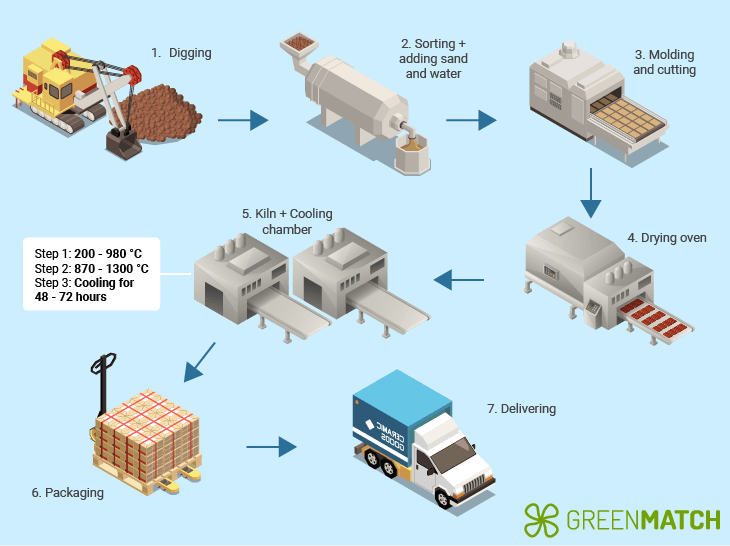

Made from clay soil, bricks are meticulously prepared, shaped, dried, and fired, ensuring their strength and longevity. Some brick structures have stood tall for over 500 years.

Their rich history and structural integrity have long been a symbol of permanence. Yet, the processes involved in their creation—clay extraction, high-temperature kiln firing, and the resultant emissions—cast a shadow on their environmental viability.

The production of traditional bricks contributes to environmental degradation, including removing topsoil, deforestation, and emissions of greenhouse gases and pollutants.

Globally, the brick industry significantly contributes to CO2 emissions, with kilns releasing over 1,072 million tonnes of CO2 annually, accounting for 2.7% of total emissions. However, the environmental impact of brick production varies widely depending on the region and the technologies used.

In this article, we delve into bricks' environmental impact to understand their eco-profile and explore whether they are as innocuous as they appear or if they come with a hidden environmental cost.

- What do we mean by Bricks?

- Environmental Impact of Brick Production

- Brick Production in Largest Economies

- Are Bricks Production Toxic?

- Are Bricks Degradable?

- Recycling and Reusability of Bricks

- Can Bricks be Sustainable?

- Environmental Impact Compared to Everyday Things

- What Are Alternatives?

- Statistics, Facts and Figures About Bricks

- Frequently Asked Questions about Bricks

What Do We Mean By Bricks?

Bricks are among humanity's oldest and most fundamental building materials. They are small rectangular blocks typically made of fired or sun-dried clay. They have been in construction for thousands of years due to their durability, fire resistance, and thermal mass properties.

They are made from clay, sand, lime, or concrete and are commonly used to build walls, pavements, and other elements in masonry construction.

Composition and Types:

- Bricks are primarily made from clay, a naturally abundant material, and can include other substances like sand, lime or concrete. The process involves moulding or cutting with wires before baking in an oven.

- A wide array of brick types exist, each serving different purposes in construction. These include but are not limited to common or building bricks, face bricks, hollow bricks, and engineering bricks, known for their high strength and low water absorption.

- Specialised bricks cater to specific needs, such as chemically resistant for environments exposed to harsh chemicals, Fire or refractory bricks for high-temperature settings, and Aesthetic bricks like the Chicago standard brick or London stock brick, named after their place of origin.

Despite their widespread use and historical significance, the environmental impact of brick production and use has become a growing concern. Manufacturing, particularly clay bricks, is energy-intensive and contributes significantly to carbon emissions, air pollution, and depletion of natural resources.

Environmental Impact of Brick Production

The environmental footprint of brick production is considerable, involving high energy consumption and significant CO2 emissions. The process involves extracting clay, an activity that can lead to soil erosion and depletion of natural resources. The subsequent firing process, which hardens the bricks, is energy-intensive and typically relies on fossil fuels.

In South Asia, brick kilns are a significant source of air pollution, contributing to respiratory and cardiovascular diseases. In addition, removing fertile topsoil for brick-making compromises soil quality and fertility, affecting irrigation water availability and food production.

Moreover, burning biomass in brick kilns releases greenhouse gases and air pollutants, contributing to air pollution and climate change. To elucidate the extent of these impacts, we present the following data in a concise and structured manner:

| Environmental Aspect | Impact |

|---|---|

| CO2 Emissions | Brick kilns, especially those using traditional methods, are a significant source of CO2 emissions. The firing process in kilns requires burning large amounts of fossil fuels. |

| Air Pollution | Brick manufacturing releases particulate matter, sulfur dioxide, and other pollutants and particulates into the atmosphere, with kilns contributing to 2.7% of total emissions. |

| Resource Depletion | The extraction of clay depletes natural resources and can lead to landscape degradation and loss of biodiversity. Nearly 25 to 26 per cent of the country’s wood production is used to burn bricks yearly, causing deforestation. |

| Energy Consumption | The production of bricks, particularly firing, is energy-intensive, contributing to the overall energy demand and associated environmental impacts. |

| Health Implication | During the dry season, kilns contribute 30-50% of the PM 2.5 in the air, leading to cardiovascular and respiratory diseases. Mean respirable silica exposures were as high as 620 µg/m3, exceeding recommended limits and resulting in worse lung function and more respiratory symptoms among brick kiln workers. |

| Waste Management | Another environmental challenge is the disposal of brick waste. While it can be recycled or reused, a significant amount remains in landfills, contributing to waste management issues. |

What is the Impact of Brick Production?

Total impact per year

Globally, brick kilns release over 1,072 million tonnes of CO2 emissions annually, accounting for 2.7% of total emissions. Additionally, the industry consumes 375,000,000 tonnes of coal annually, alongside other highly polluting fuels. In addition, the brick manufacturing industry is estimated to produce 23,300 tons of PM2.5, 15,500 tons of SO2, and 302,000 tons of CO annually. These figures highlight the significant contribution of brick production to global pollution levels.

Impact per day

Breaking down the annual impact, brick production contributes approximately 2.94 million tonnes of CO2 emissions daily, underscoring this industry's continuous pressure on the environment.

Impact per usage

The environmental impact extends beyond production. For instance, the water footprint for producing one brick is 10.48 litres, and the embodied carbon per cubic meter of clay brick is approximately 345kg.

In addition, the extraction of clay for brick-making leads to soil degradation, affecting agricultural productivity and biodiversity. Moreover, the energy required for firing results in significant CO2 emissions, with estimates suggesting that each brick could embody around 0.317 to 0.371 kg of CO2.

| Environmental Impact | Annual Contribution | Daily Contribution | Impact per Brick (kg of CO2) |

|---|---|---|---|

| CO2 Emissions | 1,072 million tonnes | 2.94 million tonnes | 0.317 - 0.371 |

| Coal Consumption | 375 million tonnes | 1.03 million tonnes | 275.4825 gm |

Environmental Impact of Different Brick Types

- Fired vs Unfired Bricks: Fired clay bricks have high embodied energy due to the firing process and significant CO2 emissions, whereas unfired clay bricks have lower embodied energy and less CO2 emissions.

- Reclaimed and Calcium Silicate Bricks: Reclaimed bricks reduce environmental impact through reuse, and calcium silicate bricks have lower CO2 emissions than fired clay bricks.

To minimise the environmental impact, solar energy could be harnessed to power the kilns for firing bricks, eliminating the need to burn fossil fuels and reducing associated greenhouse gas emissions and air pollution. Photovoltaic solar panels do not produce emissions or pollutants when generating electricity.

Brick Production in Largest Economies

Brick remains a crucial building material globally. Production is a significant industrial activity globally, especially in the largest economies where construction and infrastructure development are ongoing.

Here's a concise overview of annual brick production and the estimated CO2 emissions from this production in some of the largest economies.

| Region/Country | Annual Brick Production (billion units) | Estimated CO2 Emissions from Production (million tonnes) |

|---|---|---|

| China | 1,000 | 700 |

| India | 250 - 300 | 175 |

| Rest of Asia | 100 | 60 |

| European Union | 150 | 105 |

| North America | 8 (Concrete Blocks and Bricks) | 12 |

| South America & Africa | 30 | 9 |

China dominates brick production, with a staggering 1,000 billion units annually. This dominance translates to significant CO2 emissions, with estimates suggesting China contributes over 60% of the global total from brick production.

Meridian Brick, a leading brick supplier in North America, produces over 1.1 billion bricks annually, highlighting significant production outside Asia. On the other hand, the European Union's total production of clay bricks and roofing tiles is worth €4.9 billion, with countries like the UK producing 2 billion bricks.

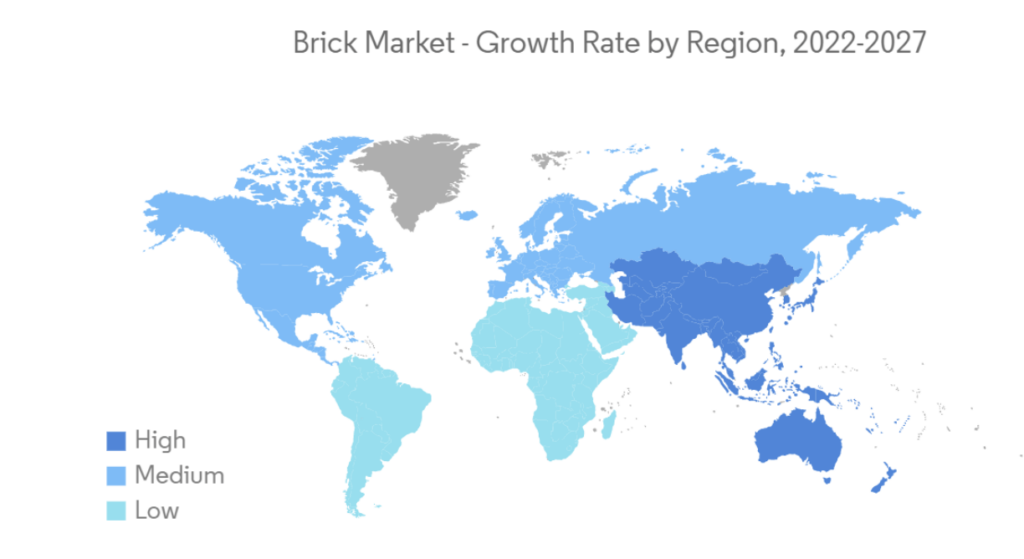

Furthermore, According to the Institution of Civil Engineers, China, India, and the United States are expected to account for almost 60 per cent of all global growth in the sector by 2025.

According to the Institution of Civil Engineers, China, India, and the United States are projected to contribute 60% of the sector's growth by 2025. In Europe, as stated by the European Commission, the Renovation Wave initiative aims to double the energy renovation rate of buildings by 2030. The focus is on renovating over 35 million buildings, which accounts for 13% of all regional establishments.

Image source: Mordor Intelligence

Are Bricks Production Toxic?

Bricks do not contain highly toxic compounds or produce toxic by-products during their lifecycle. This is because they are made from natural materials like clay.

But here is where things get a bit smoky.

In some regions, brick kilns lack proper emission controls, posing health risks to workers and nearby communities. Studies have shown that brick kiln workers often suffer worse health outcomes than unexposed controls, including reduced lung function and increased respiratory symptoms. Additionally, they experience musculoskeletal complaints and inflammation. The risk is exacerbated because many brick kilns operate in the informal sector with little regulation, leading to inadequate worker protection.

Additionally, exposure to airborne pollutants during production can lead to respiratory diseases, including chronic obstructive pulmonary disease (COPD), asthma, and pneumoconioses. Inhaling dust containing high silica concentrations during brick manufacturing poses a risk of developing respiratory diseases such as silicosis.

Are Bricks Degradable?

Bricks are primarily made from natural materials, such as clay and shale, which are abundant and considered environmentally friendly due to their natural origin. However, When fired at high temperatures, the clay particles fuse, creating a solid mass highly resistant to physical and chemical breakdown. This vitrification process is crucial for the brick's durability, making it resistant to weathering, moisture, and even fire.

One of the most compelling arguments for sustainability lies in their long lifespan. They are designed to last for generations, with an average lifespan of more than 100 years. This longevity means that the environmental impact of producing a brick is spread over a much longer. Other building materials may require frequent replacement or maintenance.

While bricks may not degrade, they are highly recyclable.

Recycling and Reusability of Bricks

Recycling and reusing bricks present a viable path towards reducing the environmental impact of construction, offering both ecological and economic benefits.

Bricks can be recycled and reused at the end of their life, reducing their environmental impact. Old bricks can be cleaned and reused in new construction projects, road bases, landscaping, or crushed for other uses. For instance, recycling one tonne of bricks can save 0.95 tonnes of CO2e, equivalent to the emissions from driving a car for 95 kilometres.

In some jurisdictions, such as Massachusetts and Portland, Oregon, brick recycling is mandated by law, reflecting a growing recognition of its environmental benefits. Bricks' recyclability makes them environmentally friendly, reducing the need for new raw materials and minimising waste.

| Impact Category | Savings per Tonne of Recycled Bricks |

|---|---|

| Greenhouse Gas Emissions | 0.95 tonnes CO2e |

| Energy Consumption | Equivalent to 0.2 households' energy for a month |

| Water Usage | Seven bathtubs (1.26 km) |

| Waste Reduction | 19 wheelie bins (1.07 tonnes) |

Can Bricks be Sustainable?

Despite the challenges in production, it is considered a sustainable building material due to its durability.

One of the most compelling sustainability features is their durability. A brick structure can last over 500 years, surpassing many contemporary building materials.

Brick buildings have excellent thermal mass, helping to regulate indoor temperatures and reduce energy consumption for heating and cooling.

However, globally, the brick industry is moving towards more sustainable practices. Innovations in kiln technology and alternative fuels are reducing brick production's carbon footprint. Salvaged from demolished buildings, reclaimed bricks are in high demand for new construction and restoration projects. They embody the circular economy principle, promoting sustainability and resource efficiency.

Environmental Impact Compared to Everyday Things

Bricks may not immediately come to mind when considering the environmental impact of everyday items. However, the production of bricks has a significant carbon footprint, which is essential to understand in the context of global efforts to reduce CO2 emissions.

Below is a comparison that provides a clear perspective:

Carbon Footprint Comparison:

- Producing 1 ton of bricks (per m³) will equate to an average CO2 emissions of 345 kg CO2.

- Smartphone: A typical smartphone has an estimated carbon footprint of 85-110 kg CO2e.

- Cup of Coffee: A single cup of coffee has a carbon footprint of around 40-50 grams of CO2e.

- Single-use Plastic Water Bottle: Has a carbon footprint of about 82.8 grams of CO2e.

- Laptop: Laptop (over its lifetime) emits 350kg of CO2.

- An average household's annual CO2 emissions emit 5-6 tons of CO2.

- Cement (per ton) production emits an average CO2 emission of 900kg.

The above provides a snapshot of how brick production's CO2 emissions compare to other common sources of emissions. For instance, a single brick may emit less CO2 than a laptop over its lifetime. However, the scale of brick production and its cumulative impact can be substantial. The production of cement, a key component in concrete, is another major contributor to CO2 emissions, dwarfing bricks per ton.

Please note that the carbon footprint of building materials is measured in tons of CO2e per square meter, with bricks significantly contributing to this metric.

Comparing Bricks with Other Building Materials

When comparing bricks with other building materials, it's essential to consider their environmental impact. Particularly, the focus should be on CO2 emissions and embodied energy.

Here's a concise comparison based on cited data from d

- Bricks Emit approximately 345kg of embodied carbon per m³, which is a significant environmental impact in terms of CO2 emissions compared to daily items like smartphones and coffee.

- Concrete: Accounts for about 80% of all embodied emissions in buildings, with reinforced concrete emitting an average of 635kg embodied carbon per m³.

- Steel and Aluminum Have the highest carbon footprint among the materials discussed, with steel sections emitting 12090kg and aluminium approximately 18009kg embodied carbon per m³.

- Wood and Softwood Timber: If sourced sustainably, they can serve as renewable resources, with an average of 110kg embodied carbon per m³ for softwood timber.

- Rammed Earth has the lowest carbon footprint, at 48kg embodied carbon per m³, showcasing its potential as a sustainable building material.

- Mud Bricks: Are considered more environmentally friendly than concrete bricks, made from natural materials and require less energy to produce

What Are Alternatives?

Exploring sustainable alternatives to traditional bricks reveals many innovative materials designed to lessen environmental impact.

These alternatives address environmental concerns and offer various cost, maintenance, and installation benefits.

Here's a list of notable alternatives:

- AAC Blocks: Autoclaved Aerated Concrete (AAC) blocks are lightweight, precast foam concrete building materials that provide excellent insulation and are easy to work with.

- Hempcrete Bricks: These bricks use hemp and limestone and absorb carbon over their lifetime. They promote temperature and humidity regulation and deliver fire resistance with a low-energy manufacturing process.

- Gent Waste Brick: Made from 63% recycled municipal waste, this lime-cured brick sequesters carbon during curing, significantly reducing embodied carbon compared to clay bricks

- Fly Ash Bricks are lighter and stronger than clay bricks. They are manufactured from industrial waste, preventing landfill dumping and reducing CO2 emissions.

- K-BRIQ: It comprises at least 90% recycled construction waste and employs a low-carbon production process that eliminates the need for virgin cement or extensive clay. This innovative approach effectively addresses the UK's brick demand-supply gap.

- Recycled Plastic Bricks: Bricks from recycled plastics reduce landfill waste and are often more durable and water-resistant than traditional bricks.

Is It Better Than Alternatives?

Bricks have been a staple in construction for centuries, and they are known for their durability and classic aesthetic. However, considering the environmental impact and the need for sustainable development, some alternatives may be better suited for specific projects.

For instance, AAC blocks and fly ash bricks significantly reduce CO2 emissions compared to traditional bricks, highlighting their environmental benefits. Additionally, they utilize industrial waste materials, further contributing to their eco-friendly credentials.

However, Bricks still hold their own regarding fire resistance, soundproofing, and thermal mass, making them a viable option for many. However, the alternatives listed are gaining popularity due to their green credentials and cost-effectiveness. Their innovative properties effectively meet the demands of modern construction.

Statistics, Facts and Figures About Bricks

By examining the statistics, facts, and figures about bricks, we comprehensively view the industry's scope and environmental implications.

Global Brick Production and Market Size:

- Between 2017 and 2019, the global production of bricks was approximately 32.4 billion units, with a 5-6% growth rate over the previous decade.

- India and China are significant contributors, with India producing more than 10% of the world's bricks, making it the second-largest brick producer after China.

- The brick industry's market size was £57.28 billion in 2019, with a forecasted compound annual growth rate (CAGR) of over 3% during 2020-2025.

- They contribute 20% of the world's black carbon emissions, with coal being the primary fuel source.

- The industry employs around 15 million workers in India, often under harsh conditions.

- The United States, United Kingdom, and Australia also contribute to the global brick market but to a much lesser extent.

- The European Union's total production of clay bricks and roofing tiles is worth approximately €4.9 billion, with countries like the UK producing over 2 billion bricks.

Production by Region:

- United States: Total shipments of clay construction bricks amounted to approximately 7.8 billion units in 2019, with the industry being valued at £1.37 billion and employing around 6,000 people.

- United Kingdom: The country produced 2 billion bricks in 2015 and 2.5 billion bricks in 2019, highlighting a growth trend. The brick and tile manufacturing industry employs around 18,000 people.

- Europe produces approximately 21 billion clay bricks annually, with the EU’s total production of clay bricks and roofing tiles valued at roughly £3.73 billion in 2018.

- Australia annually produces about 1.5 billion clay bricks, with the clay and concrete brick manufacturing industry valued at £2.13 billion.

- India: In India alone, the brick industry consumes 30-35 million tonnes of coal annually, making it the second-highest coal consumer after the steel industry.

- Europe has a rich history of brickmaking, with modern production focusing on sustainability and reducing environmental impacts.

- China alone accounts for approximately 66.67% of global brick production, followed by India at 13.33%.

Future Projections and Sustainability:

- The Global Brick Pavers Market is projected to reach £1.03 billion by 2027, indicating an increasing demand for innovative and sustainable brick materials.

- Sustainability Efforts: With the industry's growth, there's a significant push towards adopting eco-friendly production methods and materials to mitigate environmental impact.

Frequently Asked Questions about Bricks

Bricks can have a negative environmental impact due to the energy-intensive production process. Firing bricks in kilns typically requires burning fossil fuels, which releases carbon dioxide and other pollutants into the atmosphere. Additionally, clay extraction for brick manufacturing can lead to soil degradation and landscape disruption.

Bricks and wood have different environmental impacts. While bricks offer durability and can be recycled, their production is energy-intensive and emits significant CO2. Wood is renewable and stores carbon, but its sustainability depends on responsible forestry practices. Overall, wood has a lower environmental impact when sourced sustainably.

Bricks have a lower environmental footprint than concrete in terms of CO2 emissions during production. One tonne of clay produces approximately 2.4 kilograms of CO2, whereas one tonne of cement produces one tonne of CO2. However, concrete’s thermal mass and durability can offset its environmental impact over a building’s lifetime.

Recycled bricks cut costs, reduce carbon emissions by more than 40 per cent, and save energy. Using reclaimed bricks also prevents additional environmental damage from new brick production and reduces landfill waste.

Bricks that incorporate recycled materials or are made with alternative, less energy-intensive methods are considered more eco-friendly. Examples include bricks made with fly ash or those that are unfired. Additionally, bricks produced in high-efficiency kilns with cleaner fuels have a reduced environmental impact.

Inemesit is a seasoned content writer with 9 years of experience in B2B and B2C. Her expertise in sustainability and green technologies guides readers towards eco-friendly choices, significantly contributing to the field of renewable energy and environmental sustainability.

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?

- Are Bricks bad for the environment?

- What do we mean by Bricks?

- Environmental Impact of Brick Production

- Brick Production in Largest Economies

- Are Bricks Production Toxic?

- Are Bricks Degradable?

- Recycling and Reusability of Bricks

- Can Bricks be Sustainable?

- Environmental Impact Compared to Everyday Things

- What Are Alternatives?

- Statistics, Facts and Figures About Bricks

- Frequently Asked Questions about Bricks