Answer these simple questions and we will find you the BEST prices

Which type of solar quotes do you need?

It only takes 30 seconds

100% free with no obligation

Get up to 3 quotes by filling in only 1 quick form

Slash your energy bills by installing an energy efficient boiler

We’ve helped over 500,000 homeowners reduce their carbon footprint

- GreenMatch

- Boilers

- Condensing Boilers

- How Efficient is a Condensing Boiler?

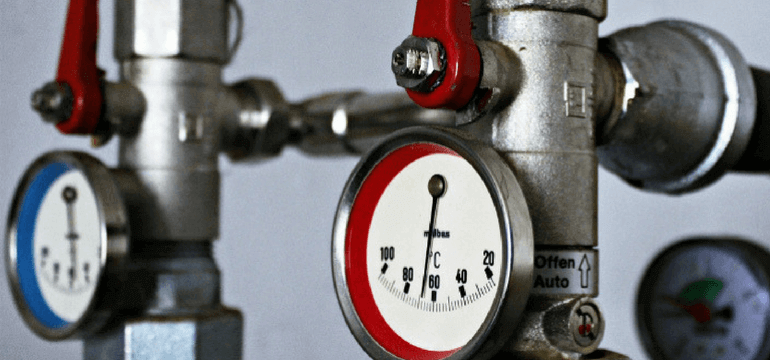

How Efficient is a Condensing Boiler?

What Is the Difference between a Conventional Boiler and a Condensing Boiler?

Deciding for the best condensing boiler type for your individual needs can be hard. However, getting the right information can simplify the decision-making process greatly and can afford you the best condensing boiler price. That is why within this article you will receive a crash course into boilers, including how to find the best condensing boiler types and boiler suppliers.

In conventional heating systems (gas boilers, for example), the heated gases pass through the boiler’s heat exchange surface, transferring the generated energy to the heat distribution system such as the underfloor heating and radiators. Afterwards, the combustion gases are released into the atmosphere through the boiler’s flue.

Thus, a certain amount of heat is lost because, together with the gases, a considerable amount of steam that forms during the burning process is being pushed out. Due to this, the released steam carries an untapped amount of evaporation energy.

This is where a condensing boiler becomes the smart, ecological, and cost-effective choice in comparison to conventional boilers as they are capable of transforming the evaporation energy into heat.

By simply filling in your personal preferences in the contact form at the beginning of this page, you can receive up to 4 quotes with the best suppliers for your individual needs. It is free of charge and no-obligation.

- Quotes from local engineers

- Payment by finance available

- Save up to £975

It only takes 30 seconds

Condensing Boilers Can Ensure a 90% Efficiency Rate

Not only is the condensing boiler a good option if you are concerned about your carbon footprint but condensing boiler manufacturers also claim that the efficiency rate of their products can reach up to 98%. Generally, conventional boilers can only reach 70-80% efficiency.

These high-efficiency boilers owe a great deal of their heat conversion to their combustion chamber. The way that these work is that the heat exchanger extracts not only the heat resulting from fuel burning but also the thermal energy that derives from water vapour condensation and transfers it to the house heating system.

Using the above terminology, it can be said that the condensing boilers deliver the highest calorific potential in terms of heating output, while ordinary gas or electric boilers provide the lowest calorific value. Hence, through condensation, the condensing boiler is able to deliver an extra 10% to 15% efficiency rate.

In order to quantify the difference between the lowest and highest calorific values for a condensing boiler, it is important to take into account the type of fuel the boiler runs on. For natural gas, this difference is about 11%. This means that the boiler efficiency rate can reach up to 90-91% at full condensation (80% from fuel burning and 11% from steam condensation).

In a condensing boiler high-performing heat exchanger, the released gases are cooled to a temperature level that is almost equal to the water temperature from the reverse loop. Therefore, the coefficient of efficiency approaches the 91% mark, and therefore, almost reaches the boiler’s physical limitation.

The extent to which the condensing boiler can fully utilise the thermal energy resulting from condensation depends primarily on the given temperature of the heating system.

The lower the temperature of the water entering the condenser, the more efficient the gas cooling process will be. Subsequently, the condensation effect can be utilised at its full potential. Thus, if you wish to enhance the overall performance of your heating system, it is important to give greater importance to the issue of maximising the condensation effect within your boiler.

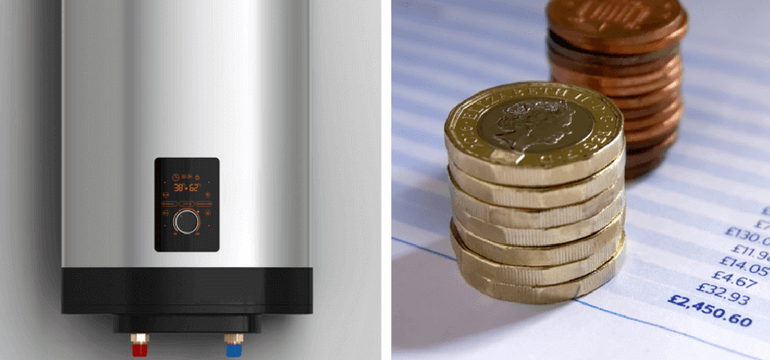

This table summarises the information about the condensing costs of different types of boilers. This will give you a better understanding about the condensing boiler efficiency rate in terms of what may show up on your energy bill.

| Boiler Type | Flat | Semi-Detached | Detached | Efficiency |

|---|---|---|---|---|

| Old gas heavy weight | £790 | £1,210 | £1,720 | 55% |

| Old gas light weight | £670 | £1,020 | £1,450 | 65% |

| New non-condensing | £580 | £850 | £1,210 | 78% |

| New condensing | £450 | £740 | £1,050 | 92% |

*Source: Sedbuk

How Does a Condensing Boiler Work?

The functioning principles of a condensing boiler have been known for one hundred years, but its use has become possible only recently. This is because condensing boiler manufacturers can now make use of technological advances in the field of stainless steel and corrosion-resistant alloy design. But how do condensing boilers work?

Upon cooling, the water vapours within the boiler turns into liquid through the condensing process. This releases a certain amount of thermal energy.

The boiler condensation occurs in a specifically designed heat exchanger, that absorbs the heat and passes it to the heating system. While in a conventional boiler the aim is to avoid the condensation process, in a condensing boiler this same process is essential for the production of heat.

The amount of heat that can be generated by burning a unit of fuel, including the heat released from steam condensation, is called the highest calorific value. The same amount of produced heat, without counting the thermal energy that results from condensation, is called the lowest calorific value.

More on the Mechanics of a Condensing Boiler

Condensing boilers have a built-in fan installed close to the heat exchanger which works with a speedometer. Due to this, condensing boilers come with a closed combustion chamber connected to a coaxial flue through which the combustion gases are released. The control over the fan’s speed helps maintain an optimal combustion ratio of air and gas. In order to minimise the loss of heat stemming from the flue gas, it is important for the heat exchanger to allow for water vapour condensation to take place.

The condensation process is at its peak when the heat exchanger surface is equal or below the dew point temperature. The dew point temperature is the most reliable unit of measure for the humidity and air comfort. Under normal conditions, the dew point for natural gas is around 57 degrees Celsius. Hence, in order for the boiler to work in condensing mode, the coolant temperature in the reverse loop should not exceed 57 degrees Celsius.

If the above conditions are not reached, then the efficiency rate of the condensing boiler will decrease. Even in this situation, the boiler will still be 4-5% more efficient than a conventional boiler.

The higher the coefficient of performance (COP) of a condensing boiler, the lower the heating system temperature will be. Thus, a condensing boiler will be more efficient if it is coupled with water-based underfloor heating with the flow temperature of 40 to 45 degrees Celsius.

Since there is no recommended minimum temperature for the coolant, a boiler that is connected to an underfloor heating system can work without special temperature-lowering devices. However, this only applies for large area floors and only if the heating system does not fluctuate drastically.

Some Practical Recommendations on the Use of Condensing Boilers

By using a condensing boiler you will improve the overall comfort level delivered by your heating system, and reduce the gas consumption rate by 15-20%.

What Are the Best Condensing Boiler Types?

There are two main types of condensing boilers: system boilers and combi boilers. The system boiler is a good choice for larger houses or for houses that have low water pressure. The combi boiler is the ideal choice for houses that require heating on demand.

That being said, both of the condensing boiler types can come in different shapes and sizes. Here is an overview of the various types:

Find the Best Boiler Offers

It can be hard to decide between all these different types of boilers, especially when weighing the benefits of paying more for purchasing. The good thing with condensing boilers is that although their cost can be higher at the very beginning, the investment pays off in time by saving money on the electricity bill.

If you have decided to purchase a boiler but are not sure which type fits your needs best, we are here to help. Simply fill in the form on this page with your personal preferences and information, and we will provide you with up to 4 different suppliers. The service is free, without obligation, and only takes a minute.

- Quotes from local engineers

- Payment by finance available

- Save up to £975

It only takes 30 seconds

We strive to connect our customers with the right product and supplier. Would you like to be part of GreenMatch?